Natural graphite is a critical industrial mineral. It’s widely used in applications ranging from electric vehicle (EV) batteries and energy storage to refractory materials and steel production. At EPIC Powder Machinery, we focus on the efficient grinding and classification of natural graphite.

The Role of Natural Graphite in Industry

Driven by the rapid growth of the EV market and renewable energy storage systems, natural graphite demand is increasing worldwide. In 2024, the global graphite market was valued at approximately USD 15.67 billion. It is projected to reach USD 36.4 billion by 2030, growing at a compounded annual growth rate (CAGR) of 15.1%. Graphite’s superior electrical conductivity, lubricity, and thermal stability make it an indispensable anode material for lithium-ion batteries. It’s a key component in electrodes used in electric arc furnaces for steel manufacturing.

Grinding Technologies: Air Classifier Mills and Jet Pulverizers

Efficient ultrafine grinding and classification are essential for producing graphite powders with the required particle size distribution and purity for high-performance applications. Two of the principal milling technologies utilized in the industry are:

•Air Classifier Mills (ACM): These mills integrate grinding and classification within a single unit. The graphite feedstock is fed into a high-speed rotating crushing disc where impact, shear, friction, and collision forces reduce particle size. The ground material is then transported by airflow to a classification wheel with adjustable speed, allowing precise control over the final product fineness. Coarser particles are returned to the grinding zone for further size reduction.

•Jet pulverizers: In jet milling, high-velocity air jets accelerate particles into collisions with each other, enabling particle size reduction without mechanical grinding elements. Jet mills are especially suited for producing ultra-fine powders with narrow particle size distributions and minimal contamination, making them ideal for high-purity graphite.

Performance and Data Highlights

At EPIC Powder Machinery, our MJW-A air classifier mill exemplifies state-of-the-art double-shaft concentric design, ensuring uniform feeding and strong impact forces combined with centrifugal effects for efficient size reduction. The frequency-regulated classification wheel facilitates highly consistent and narrow particle size distributions crucial for demanding battery-grade graphite applications.

Recent industry studies emphasize the importance of advanced milling techniques for energy and cost efficiency. For example, bead milling can reduce ultrafine graphite production time from 72 hours (traditional ball milling) to just 10 minutes, while maintaining similar product morphology and crystalline quality. Data from our proprietary air classifier mills show similar improvements in process throughput and product uniformity using optimized classifier wheel speeds and airflow rates.

Industry Analysis and Market Drivers

The Asia-Pacific region dominates graphite production and consumption due to its abundant reserves and expansive battery manufacturing infrastructure. The demand surge is fueled by:

• The proliferation of EVs requiring approximately 80 kg of graphite per battery.

• Expansion of renewable energy storage systems reliant on lithium-ion batteries with graphite anodes.

• Growth in steel production using electric arc furnace technology, which uses graphite electrodes.

Sustainability considerations are influencing graphite processing innovations. Natural graphite mining and synthetic graphite production both confront environmental challenges such as ecosystem disruption and carbon emissions. Cleaner, more efficient grinding technologies like air classifier mills and jet mills contribute to reducing the environmental footprint of graphite powder production.

Technical Considerations for Equipment Suppliers

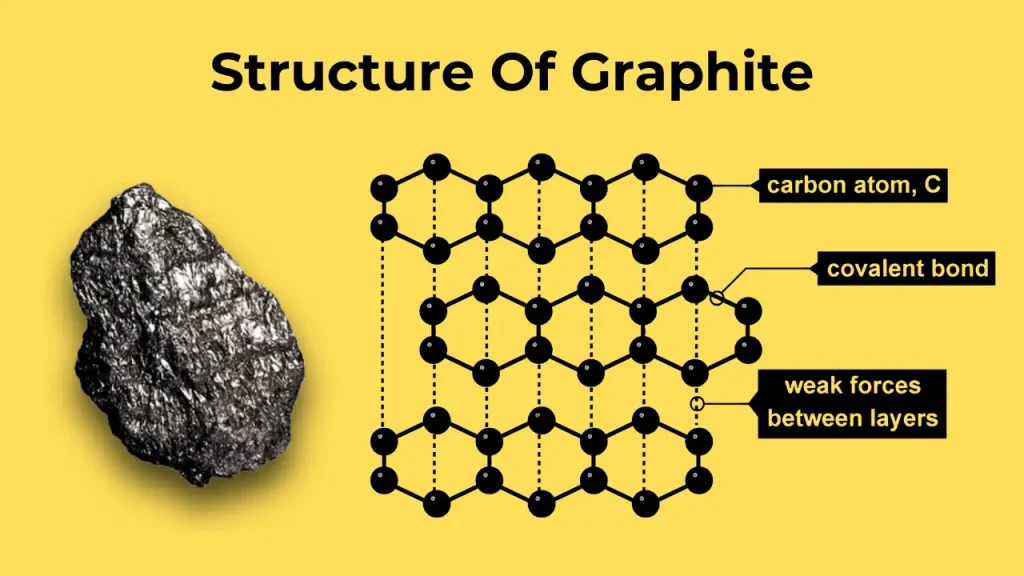

For equipment suppliers and technical specialists, understanding material properties and process customization is paramount. Natural graphite’s lamellar crystalline structure demands mills capable of handling high lubricity and achieving uniform particle shape and size. Classifier speed, airflow rate, and grinding disc or jet velocity are critical operational parameters.

Additionally, closed-loop systems with integrated dust collection and inert gas atmospheres may be necessary for processing to prevent oxidation and contamination while ensuring safety.

epic Powder

The classification of natural graphite using air classifier mills represent advanced technological solutions that meet the evolving demands of high-growth industries, such as EV batteries and steel production. EPIC Toz Makinaları’s equipment, supports manufacturers in achieving high-efficiency production of uniform, high-purity natural graphite powders. Contact us today for a tailored solution.