Choosing a good classifier can help improve the efficiency and reduce the cost of your powder classification. Below, please see several best-selling air classifier models from Epic Powder for your reference.

1. HTS Multi-Rotor Air Classifier

The HTS is engineered for applications where consistency and top-cut control are non-negotiable. Its unique design features multiple classification rotors stacked vertically, creating several classification stages within a single unit.

- How It Works: Material is fed from the top and processed through each successive rotor stage. This multi-pass system ensures that only particles meeting the strictest fineness requirements pass through the final rotor, resulting in an exceptionally sharp cut and a narrow particle size distribution.

- Ideal For: Ultra-fine calcium carbonate for plastics, high-purity talc for cosmetics, and other high-value minerals where D97 is a critical specification.

2. ITC Inertial Classifier

The ITC operates on a dynamic inertial principle, offering a robust and energy-efficient solution without the need for a large footprint.

- How It Works: The feed material is accelerated and injected into the classification chamber. A powerful vortex generator creates a strong centrifugal field, while adjustable guide vanes fine-tune the cut point. The inertia of coarse particles causes them to be ejected, while fines follow the air stream.

- Ideal For: General-purpose classification of calcium carbonate, talc, and other non-metallic minerals where high throughput and operational simplicity are key.

3. TDC Turbo Twin Double Classifier

Why settle for one product when you can make three? The TDC is essentially two classifiers in one, designed for maximum product flexibility

- How It Works: The machine features two independent classification rotors stacked in series, each with its own drive and speed control. The first stage extracts the coarse fraction, the second stage extracts the medium fraction, and the fines are collected separately.

- Ideal For: Producers looking to diversify their product portfolio from a single material stream, such as simultaneously producing coarse, medium, and fine grades of GCC.

4. MBS Air Separator

Based on the time-tested mechanical air separator design, the MBS is a workhorse for dedusting and coarse particle separation

- How It Works: A slow-rotating distribution plate disperses the material into an upward air stream. Fine particles are carried over into the cyclone, while coarse particles fall through the cage rotor for collection. Its simple and robust design ensures low maintenance and high reliability.

- Ideal For: Pre-classification before grinding mills (to improve mill efficiency) or for the dedusting of sands, minerals, and recycled materials.

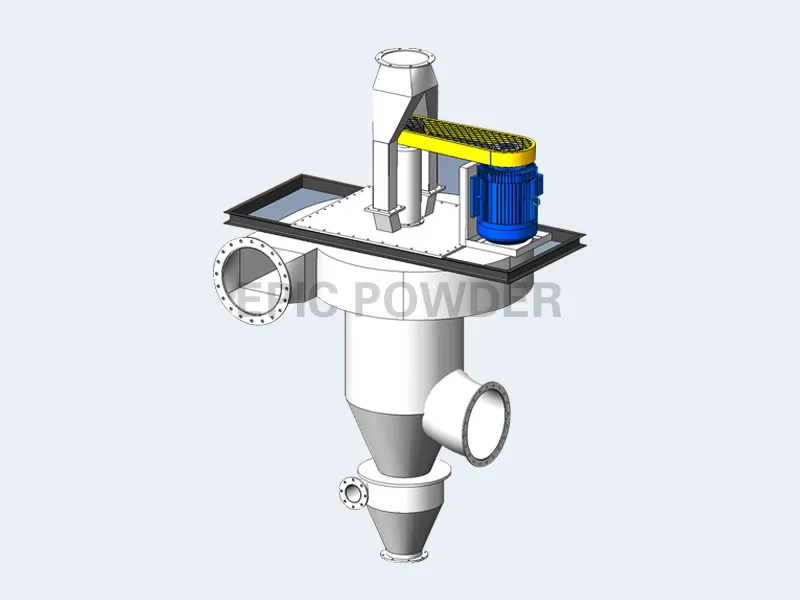

5. CTC Centrifugal Classifier

The CTC is built for toughness. Its centrifugal design is perfectly suited for handling sharp, abrasive, and granular materials

- How It Works: Material is fed into the center of a high-speed rotating plate and flung outward by centrifugal force. As it passes through a powerful cross-flow of air, fines are carried away while coarse particles continue their trajectory into a collection hopper. Key wear parts are lined with ceramic or polyurethane for maximum longevity.

- Ideal For: Classifying silica sand, quartz, feldspar, and abrasive recycled materials.

Quick Decision Guide for Air Classifiers by Epic

- HTS Air Classifier (Multi-Rotor Type): Pros: Amplified output, adjustable for varied densities—client-proven scalability. Cons: Slightly higher complexity than single setups.

- Air Classifying ITC: Pros: Broad fineness, sensor-driven precision. Cons: Requires full system (cyclone + fan).

- Centrifugal Classifier CTC: Pros: Compact, low-cost entry. Cons: Coarser range limits ultra-fine use.

- Powder Air Separator MBS: Pros: Massive scale, wear-proof. Cons: Higher upfront power draw.

- Turbo-Twin Double Classifier TDC: Pros: Superfine + energy-efficient. Cons: Specs less detailed for capacity planning.

Match your needs: Prioritize fineness for quality-driven apps (TDC or Multi-Rotor), capacity for bulk ops (MBS), or cost for starters (CTC). Epic Powder offers non-standard customizations, 1-year warranties, and installation support—contact them for material-specific testing.

Ready to upgrade your powder classification? Explore Epic Powder’s full range air Classifiers at powder-air-classifier.com or request a quote today. With the expert-guided designs, you’ll achieve sharper cuts, higher yields, and greener operations.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Jason Wang, Senior Engineer