In the field of powder processing, air classification technology is one of the primary deep-processing techniques for powders. It’s crucial for achieving powder refinement in the inorganic non-metallic materials sector. As modern industry demands higher control over micron-level particle size, the key challenge has become producing uniform ultrafine powders efficiently and energy-savingly.

Classification Principles and Types

• Broad-Sense Classification: Separates material particles based on differences in their physical characteristics (such as size, shape, density, magnetism, radioactivity) according to production requirements. The common method is screening through meshes, suitable for particles above 50μm. However, screening equipment often occupies large space and can cause secondary crushing.

• Narrow-Sense Classification: Utilizes the difference in the resultant force experienced by particles of different sizes in a fluid medium, causing them to follow different trajectories, thus achieving separation. Based on the medium, powder classification is divided into dry (using air) and wet (using water or other liquids) methods. Wet classification requires subsequent dewatering and drying of particles, consumes significant water, and has higher energy consumption. Consequently, dry classification (air classification) finds wider application in industrial production.

Classification Equipment

Air classifiers can be categorized into two types based on the presence of rotating internal parts: Static (or stationary) Air Classifiers and Dynamic Air Classifiers.

01 Static Air Classifiers

These have relatively simple structures and are easy to maintain, but offer lower classification precision and fewer means for adjusting particle size. Based on the dominant force, they are divided into Gravitational and Centrifugal classifiers.

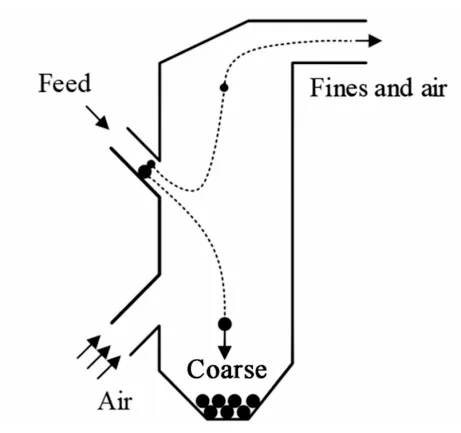

① Gravitational Classifier: This method classifies particles based on differences in the gravitational force and settling velocity of different sized particles, and their interaction with the fluid. Depending on the fluid flow direction and force field, it can be vertical or horizontal flow.

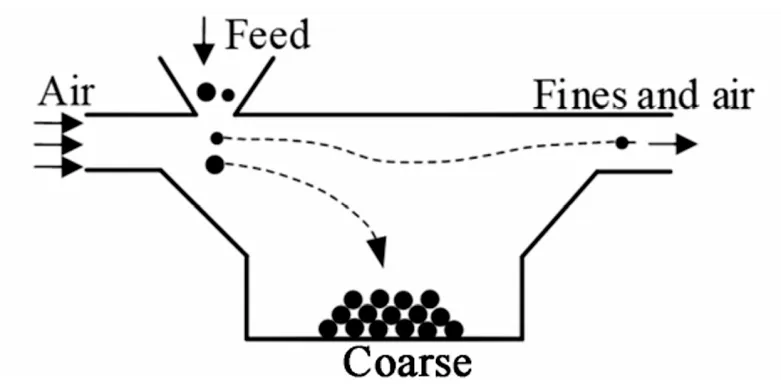

Gravitational classifiers were the earliest type developed and are now used in various fields. However, with advancing fine industry and powder technology, their classification efficiency and precision are limitations. Efficiency can be improved through multi-stage separation, making zigzag classifiers a current research focus. Coupling vertical and horizontal flows can also optimize the internal flow field. Advantages like low pressure drop, good heat dissipation, and large capacity make them suitable for pre-processing larger particles or materials not requiring precise classification.

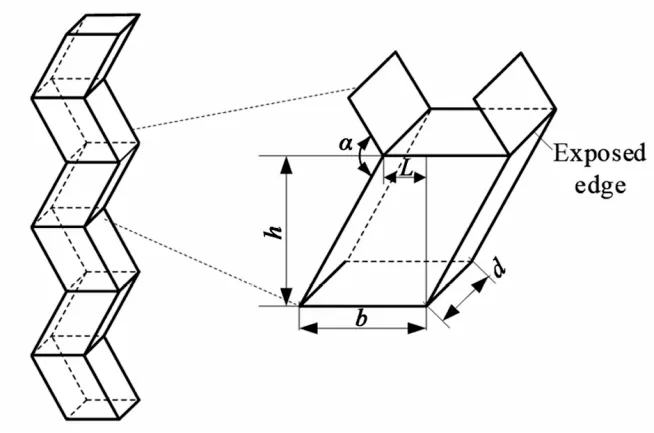

② Centrifugal Classifier: In centrifugal classification, coarse and fine particles separate by moving in different directions under the influence of air drag and centrifugal forces. Static centrifugal classifiers typically use tangential inlets creating high-speed rotating airflow or guide vanes to make particles rotate. They are simple, low-cost, and easy to maintain. Compared to gravitational types, they offer significantly improved efficiency and precision, leading to wider industrial use. Current research often focuses on the inlet structure of cyclone classifiers or adding inlets. Mechanistic studies on particle collisions and agglomeration within these classifiers are fewer; tools like CFD-DEM can analyze particle interactions to further reveal the classification mechanism.

02 Dynamic Air Classifiers

Featuring internal rotating parts, dynamic air classifiers offer substantially higher classification efficiency and precision compared to static ones, making them the mainstream equipment today. Their internal structure is more complex, leading to higher operating costs and energy consumption, but they provide superior efficiency, more adjustable parameters, and are better suited for precision classification.

Based on the rotor cage orientation, they are divided into Vertical and Horizontal Vortex Air Classifiers. The orientation significantly impacts performance:

• Mechanical Structure: Horizontal classifiers have a cantilever-supported rotor cage, requiring larger spindles and bearings. Vertical classifiers have a more complex overall structure and higher manufacturing costs.

• Classification Efficiency: Vertical classifiers can ensure classification occurs over more than 90% of the rotor cage’s circumference regardless of feed method. Horizontal classifiers typically have single-side air intake, leaving at least a quarter of the area non-participatory.

• Classification Precision: Vertical classifiers allow air intake from all sides, creating a stable flow field and yielding uniform product size. In horizontal types, air velocity is higher at the rotor bottom than at the top/sides, widening the classified size range and potentially allowing coarse particle carry-over.

• Pressure Drop: Airflow in vertical classifiers undergoes multiple direction changes, resulting in higher pressure loss. Horizontal classifiers are compact with fewer internal components, thus having lower pressure loss.

Conclusion

From simple gravitational separation to precision vortex separation, air classification technology has become a key engine. It’s driving the high-quality development of the powder industry. As understanding of particle behavior and flow field dynamics deepens, future air classification equipment will become more efficient. This progress will provide more powerful powder processing solutions for strategic emerging fields like new materials and new energy.

Epic Powder Machinery

Using the right classification technology is essential for achieving the precise particle size distribution your application demands. At Epic Powder Machinery, we specialize in advanced air classification solutions designed for maximum efficiency, precision, and reliability. Whether you are in the new materials, pharmaceuticals or any other industry requiring fine powders, Epic Powder provides the tailored equipment for you. Let our expertise help you unlock new levels of performance in your powder processing operations.