Q: What is a Turbo Air Classifier?

A: A turbo air classifier, also known as a static classifier, is a highly efficient air classification device widely used in the powder processing industry. Its core function is to precisely separate powder materials into coarse and fine products based on particle size.

Q: How does a turbo air classifier work?

A: The working principle is based on centrifugal sedimentation. The process can be summarized in the following steps:

1. Material and Air Mixing: The powder material is mixed with air to form a gas-solid two-phase flow, which enters the classification chamber through the top feed inlet.

2. Forming a Rotating Flow Field: Through carefully designed tangential air inlets or fixed guide vanes, the airflow forms a high-speed rotating vortex flow field within the cylindrical or conical classification chamber.

3. Particle Separation by Forces: In the rotating flow field, particles of different sizes are subjected to two main forces:

◦ Centrifugal Force: Tries to throw particles toward the chamber wall.

◦ Drag Force: Tries to pull particles toward the vortex center.

◦ Coarse Particles: Due to their larger mass, centrifugal force dominates. They are thrown toward the wall, slide downward along the wall under gravity and secondary airflow, and are discharged from the bottom coarse outlet.

◦ Fine Particles: Due to their small mass, drag force dominates. They are drawn into the low-pressure area at the vortex center (the “vortex core”).

4. Fine Powder Collection: Fine particles are carried upward by the airflow and discharged through the central outlet pipe at the top into a downstream collection system (e.g., cyclone separator or bag filter).

5. Key to Precision — Secondary Air: Most modern Turbo Air Classifiers feature a secondary air (or adjustment air) inlet. This airflow is introduced tangentially into the lower part of the chamber, creating a secondary vortex that counter-rotates against the main vortex. It “washes” or “re-classifies” the descending coarse particles, blowing any entrained fine particles back into the main classification zone. This significantly improves classification precision and ensures the purity of the coarse product.

By adjusting the primary airflow velocity, the balance between centrifugal and drag forces can be altered, allowing flexible control over the cut point. Higher airflow increases centrifugal force, resulting in finer separation.

Q: What are the main components of a Turbo Air Classifier?

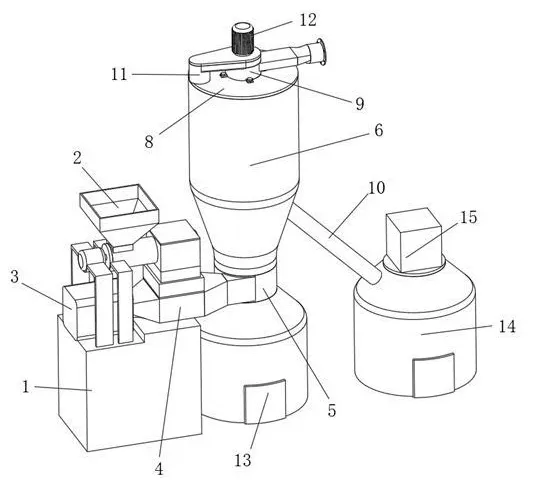

A: Key components include:

Feed system: Ensures uniform and stable dispersion and feeding of material.

Classification chamber: The core where the vortex flow field forms and separation occurs.

Guide mechanism: Fixed guide vanes or tangential inlets to generate stable, uniform rotating airflow.

Secondary air system: Provides adjustable secondary air, crucial for high classification precision.

Coarse outlet: Located at the bottom for discharging coarse particles.

Fine outlet: Located at the top center for extracting fine powder-laden airflow.

Q: What are the advantages of a Turbo Air Classifier?

A: Key advantages include:

Simple and reliable structure: No high-speed rotating parts (static classification), resulting in low wear, low failure rate, low maintenance, and high reliability.

High classification efficiency: Especially with the secondary air system, it achieves sharp separation with narrow particle size distribution and reduced fine content in coarse product.

Easy operation and adjustment: Product fineness can be continuously adjusted over a wide range simply by changing airflow velocity.

Large processing capacity: The design supports large-scale powder processing, suitable for industrial continuous production.

Relatively low energy consumption: Typically lower than dynamic classifiers since no large rotor is required.

Q: Where is the Turbo Air Classifier commonly used?

A: It is suitable for medium to high-end precision classification in various industries, including:

Non-metallic minerals: Ultrafine processing of calcium carbonate (GCC and PCC), kaolin, talc, quartz, graphite, mica, etc.

Chemicals and fillers: Aluminum hydroxide, flame retardants, pigments and fillers, powder coatings, etc.

Other materials: Also used in food, pharmaceuticals (inert excipients), metallurgy, magnetic materials, and more.

Q: How does a Turbo Air Classifier compare to a Dynamic Classifier?

A: Vortex (static) and dynamic (with high-speed rotating rotor) classifiers are two mainstream air classification technologies.

Turbo Air Classifiers offer advantages in maintenance cost, reliability, and energy consumption due to the absence of moving parts. They are ideal for large-volume, medium to high-precision applications where extreme fineness is not required.

Dynamic classifiers provide higher precision, finer cut points (down to sub-micron levels), and greater flexibility by adjusting rotor speed. However, they have more complex structures, higher costs, maintenance requirements, and energy consumption. They are typically chosen for applications demanding ultra-fine products and tight particle size distribution.

About Epic Powder

At Epic Powder, we are dedicated to providing advanced powder processing solutions that enhance efficiency, precision, and sustainability. Our Turbo Air Classifiers are engineered to deliver exceptional performance across a wide range of industries, ensuring optimal particle size distribution and product quality. With a focus on innovation and reliability, Epic Powder supports your production goals through cutting-edge technology and expert service. Trust us to help you achieve finer results and maximize the value of your powder products.