Air classifying mills are widely used in industries requiring precise particle size control and contamination-free processing, such as pharmaceuticals, chemicals, and fine ceramics. One of their key advantages is ease of cleaning, which ensures product purity, reduces downtime, and complies with strict hygiene standards. The ease of cleaning primarily stems from their enclosed design, compact structure, disassembly-friendly components, intelligent control system, scheduled maintenance, and material selection. These factors work together to facilitate efficient cleaning and maintenance, extending equipment service life and improving production efficiency.

Enclosed Design

Air classifying mills operate within a fully sealed environment during grinding and classification. This design effectively contains dust, minimizing environmental pollution and keeping the internal system relatively clean, which simplifies cleaning. The enclosed structure also prevents dust and debris from escaping, reducing the effort required for cleaning.

Compact Structure

The mill’s compact design takes up minimal space, making the entire system clear and easy to inspect and clean. The streamlined structure leaves no hard-to-reach areas, improving cleaning efficiency. Additionally, the compact layout enhances operational stability by reducing vibration-induced dust generation.

Easy Disassembly and Installation

Air classifying mills are designed for maintenance convenience. Key components such as the classifying wheel and grinding disc can be easily disassembled and reinstalled. This allows thorough cleaning and servicing of individual parts when needed.

Intelligent Control System

Modern air classifying mills are often equipped with smart control systems that simplify operation and reduce manual intervention. The system monitors the operating status of critical parts including the motor, bearings, and fan. It provides timely alerts when cleaning or maintenance is required, helping to sustain cleanliness and operational efficiency.

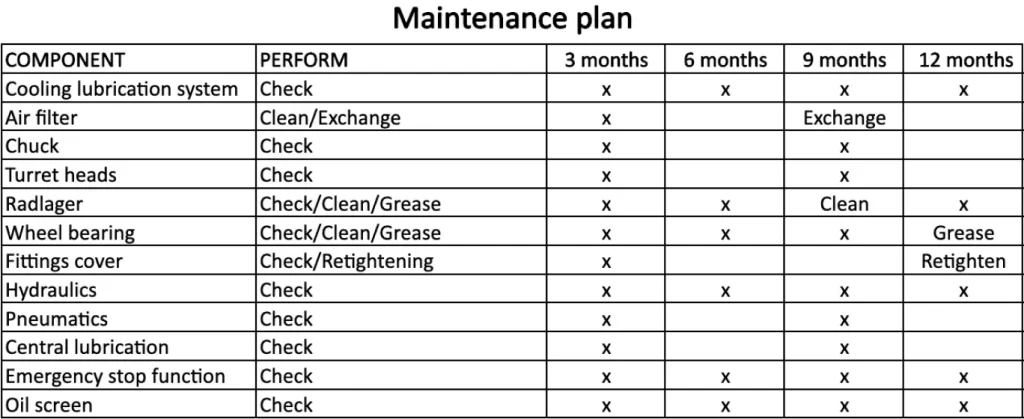

Scheduled Maintenance Plan

To maintain cleanliness and operating performance, a periodic maintenance plan is typically implemented. This includes regular cleaning of external and internal surfaces, removal of dust and debris, and washing or replacing filters. Scheduled maintenance helps detect and resolve issues in a timely manner, ensuring consistent and efficient operation.

Material Selection

Critical components such as hammers, tooth rings, and classifying wheels can be manufactured from materials like alumina, zirconia, or silicon carbide ceramics. These materials offer excellent wear and corrosion resistance and are easy to clean without accumulating stubborn residues over time.

When cleaning the air classifying mill, avoid using damp or chemical-laden cloths to prevent damage. Use a dry cloth or vacuum to remove dust and debris from exterior surfaces. For internal cleaning, apply dedicated cleaning agents and tools.

About Epic Powder

Epic Powder specializes in the design and manufacturing of advanced powder processing equipment, including high-efficiency air classifying mills. Our systems integrate intelligent controls, superior materials, and user-friendly maintenance features to ensure easy cleaning, minimal cross-contamination, and sustained performance. With a focus on innovation and reliability, Epic Powder supports customers in achieving high purity and productivity in demanding applications.