Introduction to Air Classifiers

Air classifiers are essential equipment in powder processing industries, utilizing airflow and centrifugal forces to separate particles based on size, shape, and density. Unlike traditional screening methods, air classifiers offer a dry, dynamic separation process that achieves precise particle size distribution (PSD) without the need for water or mechanical sieves. This technology is particularly valuable in industries requiring ultra-fine powders, where cut points as fine as d97 = 2-10 microns are common.

The principle involves feeding material into a classification zone where high-speed rotating wheels or turbines create centrifugal forces. Fine particles are carried by airflow to collection systems, while coarser particles are rejected and recycled or discharged. This results in sharp separations, high yields, and narrow PSDs, making air classifiers indispensable for enhancing product quality and process efficiency.

In today’s industrial landscape, air classifiers play a vital role in sectors such as minerals processing, chemicals, pharmaceuticals, food, cement, and advanced materials like battery powders and metal additives for 3D printing. Their value lies in improving product consistency, reducing waste, lowering energy consumption, and enabling compliance with stringent quality standards.

Applications in Key Industries

Mineral Processing

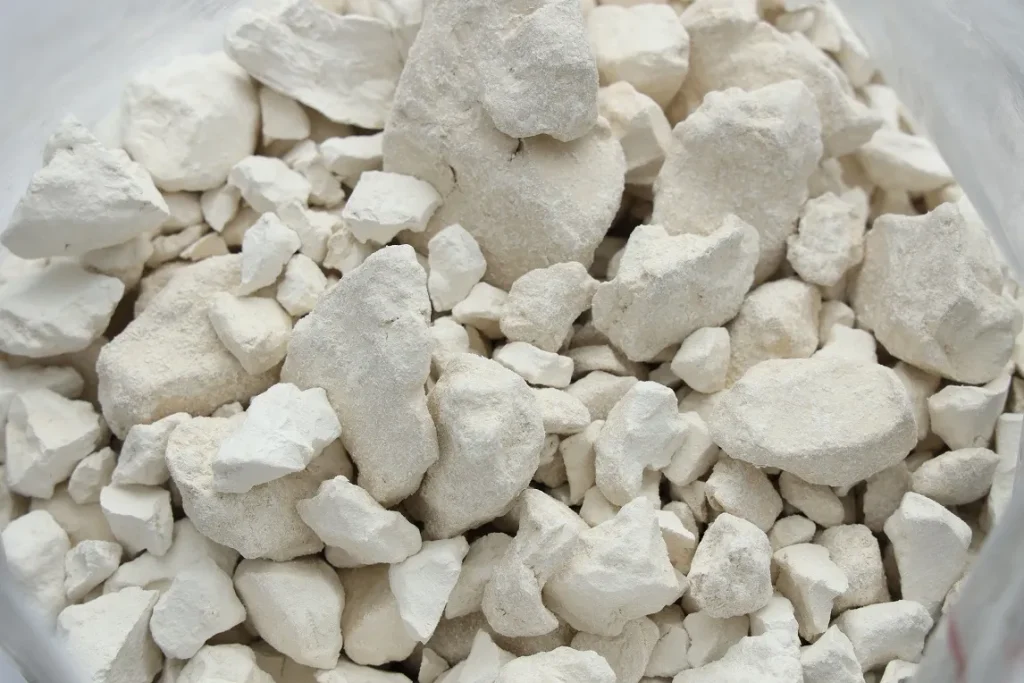

Air classifiers are widely used in mineral processing to separate fine ore particles from gangue, producing high-purity fillers like calcium carbonate (GCC), talc, kaolin, dolomite, barite, quartz, and silica. For instance, in ground calcium carbonate production, classifiers ensure precise control over particle sizes, transforming basic fillers into functional additives that enhance properties in plastics, paints, and paper.

A mineral processing client who adopted a high-efficiency centrifugal air classifier. They achieved a 30% increase in throughput while reducing energy usage by 20%. This solved the problem of inconsistent PSD in downstream applications, improving product quality and shortening processing times. The sharper cut also minimized over-grinding, reducing waste and operational costs significantly.

In aggregates and sand manufacturing, gravitational-inertial and centrifugal air classifiers recover ultrafine materials from waste streams, such as fly ash. This dry process eliminates water treatment needs, cutting environmental impact and costs compared to wet screening.

Cement and Building Materials

In cement production, air classifiers control clinker and raw material particle sizes, optimizing kiln performance and final cement strength. High-efficiency classifiers in grinding circuits have demonstrated production increases of 3-4.5% with corresponding energy savings of 4-8%. One study in a cement plant showed a 3.68% production boost and a 2.9% improvement in 28-day cement strength after classifier upgrades.

These improvements address challenges like over-grinding and inconsistent fineness, leading to lower specific energy consumption and higher profitability.

Pharmaceuticals and Fine Chemicals

Precision is critical in pharmaceuticals, where air classifiers ensure uniform particle sizes for active pharmaceutical ingredients (APIs), improving dosing accuracy and bioavailability. Stainless steel versions comply with GMP standards, preventing contamination.

In toner and pigment production, specialized ultrafine classifiers dedust powders containing titanium dioxide, achieving separations down to sub-micron levels. This enhances print quality and coating uniformity while reducing defects.

Food Processing

Air classifiers gently separate powders like flour, spices, grains, and sugar, removing impurities and achieving uniform textures. They reduce manual sorting needs, ensuring regulatory compliance for safety and quality. Case studies in grain milling report reduced waste, higher efficiency, and cost savings from lower maintenance and downtime.

Powder Coatings and Advanced Materials

For powder coatings, air classifiers ensure uniform PSD for smooth finishes, dedusting titanium dioxide-laden powders. In battery materials and metal powders for additive manufacturing, they sort particles with tight specifications, minimizing defects in 3D-printed parts.

Dry processing avoids water-related issues, lowering operating costs and environmental footprint compared to wet systems.

Benefits and Problem-Solving Capabilities

Air classifiers deliver tangible benefits:

- Precision and Quality: Sharp top cuts (e.g., d97 < 10 μm) and narrow PSDs improve end-product performance, solving inconsistencies that lead to rejects.

- Efficiency Gains: High yields (up to 99% in some systems) and continuous operation increase throughput by 15-30%, as seen in mineral and aggregate applications.

- Cost Savings: Reduced energy consumption (20-40% in optimized systems), lower maintenance (wear-resistant designs), and waste minimization translate to significant savings. For example, avoiding settling ponds in dry aggregate classification cuts water treatment costs entirely.

- Environmental Advantages: Dry processes reduce water usage and emissions, aligning with sustainability goals.

- Versatility: Handle abrasive, heat-sensitive, or contamination-prone materials without degradation.

Problems solved include clogging in fine sieving, contamination risks, high energy use in wet methods, and inconsistent quality in high-volume production.

Epic Powder’s Advanced Air Classifier Solutions

As a leading innovator in ultrafine powder processing, Epic Powder Machinery specializes in high-performance air classifiers designed for precision and efficiency. With over 20 years of experience, Epic Powder focuses on crushing, grinding, classifying, and modification technologies.

Key products include:

- HTS Horizontal Multi-Rotor Air Classifier: Engineered with German expertise, ideal for d97 3-45 μm ultrafine powders. Multiple rotors provide higher capacity and sharper cuts than single-rotor designs.

- ITC Vertical Air Classifier: Jointly developed with German and British experts, suited for d97 8-200 μm. Features internal air circulation for reduced investment and space savings.

- Other Models: Including MBS, TDC, and CTC series, offering wear-resistant options for abrasive materials and integration with ball mills for closed-circuit systems.

Epic Powder’s classifiers incorporate PLC controls for real-time adjustments, ensuring stable operation and energy efficiency. Clients report enhanced product value in applications like calcium carbonate for high-gloss coatings and minerals for advanced composites.

Epic Powder

Air classifiers are transforming industrial and technological processes by delivering precise particle separation, boosting efficiency, and driving cost reductions. Real examples—from 30% throughput gains in minerals to energy savings in cement—demonstrate their proven value in solving quality and productivity challenges.

For companies seeking powder solutions, Epic Powder‘s range of air classifiers offers reliable, high-performance options tailored to demanding applications. Investing in advanced classification technology not only elevates product quality but also positions businesses for sustainable growth in competitive markets.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative Zelda for any further inquiries.“

— Posted by Jason Wang, Senior Engineer