Air classifiers can be connected in series with multi-stage air classification systems. The HTS series classifier wheel is particularly suitable for high-intensity production environments. Its rotor is positioned horizontally and can be easily controlled and maintained via a hinged access door. The benefits of processing nickel powder with a classifier are mainly reflected in the following aspects:

Improved Product Performance and Quality

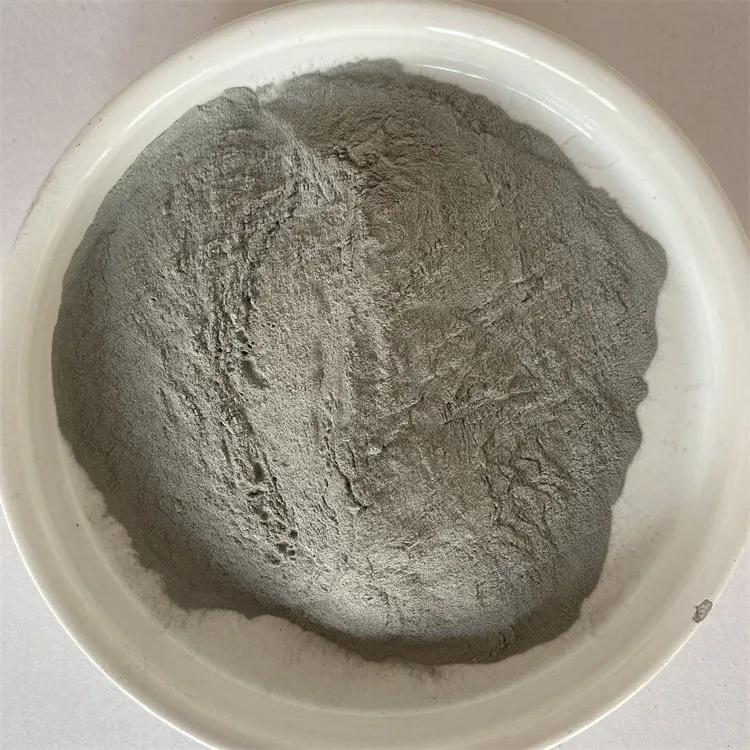

Particle Size Uniformity: The classifier separates nickel powder into distinct particle size ranges. This results in a product with a consistent particle size distribution. This is critical for many applications, as uniform nickel powder delivers better performance and stability.

Impurity Removal: During classification, certain impurities can be separated out due to differences in size or physical properties, thereby enhancing the purity of the nickel powder.

Optimized Production Process and Efficiency

Increased Production Efficiency: Pre-processing nickel powder with a classifier reduces challenges in subsequent processing steps—such as improved sintering performance and reduced agglomeration—thereby boosting overall production efficiency.

Reduced Energy Consumption: In industries requiring precise control, such as electronics and batteries, using classified nickel powder lowers energy consumption due to its uniform particle size, which simplifies handling and processing.

Meeting Specific Application Requirements

Customized Production: Different applications require different particle sizes. Classifiers enable the customized production of nickel powder with specific size distributions to meet diverse market needs.

Enhanced Application Value: Nickel powder with a uniform particle size distribution offers higher value in powder metallurgy, electronic materials, catalysts, and other fields, enabling the production of higher-performance composite materials or devices.

Environmental Protection and Sustainable Development

Reduced Waste: Precise classification minimizes waste generated from inconsistent particle sizes, reducing environmental impact.

Resource Recycling: Nickel powder of different size fractions separated during classification can be recycled and reused, improving resource efficiency and supporting sustainable development.

Operation and Principle

When processing nickel powder, classifiers primarily leverage differences in the settling velocity of mineral particles in a medium (such as water or air) to achieve separation. In the case of air classifiers, a high-speed rotating wheel within the classification chamber generates centrifugal force. It enables precise separation of fine and coarse particles. This method offers high precision and efficiency without altering the original morphology of the raw material.

In summary, classifier processing of nickel powder enhances product performance and quality, optimizes production processes and efficiency, meets specific application needs, and promotes environmental sustainability. These advantages make classifiers indispensable in nickel powder production.

Why Choose Epic Powder for Your Classification Needs?

At Epic Powder, we specialize in advanced powder processing technologies, including high-precision air classification solutions for materials like nickel powder. Our state-of-the-art classifiers ensure narrow particle size distribution, high purity, and exceptional product consistency tailored to your specific application requirements.

With a strong focus on innovation and sustainability, Epic Powder is committed to delivering efficient, eco-friendly, and reliable systems that enhance your production value and end-product performance.

Trust Epic Powder to elevate your powder processing capabilities—where technology meets excellence.