The Hidden Variable in Battery Performance

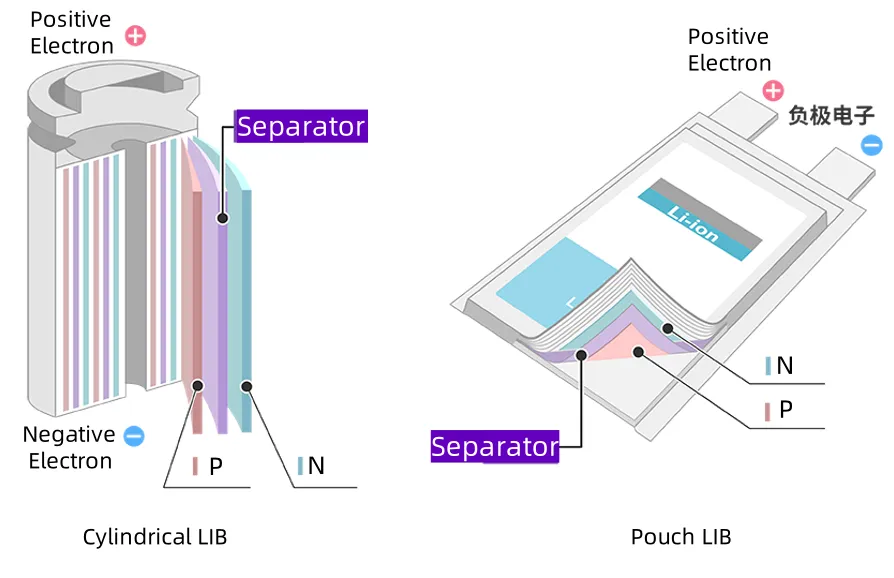

Why do two batteries with identical chemistry sometimes deliver vastly different lifespans and power outputs? The answer often lies not in the material itself, but in its physical architecture. For lithium-ion cathode powders, inconsistent particle size is the performance killer. It leads to uneven current distribution, accelerated degradation, and ultimately, a high-performing cell that never meets its theoretical potential. At Epic Powder, we understand that the journey to a superior battery begins long before cell assembly. It begins with mastering the microscopic world of powder. This is where precision classification of battery powder transforms from a manufacturing step into a critical performance enhancer.

Three Ways Precision Grading Elevates Battery Performance

The “Traffic Flow” Analogy: Why Uniformity is Key

Imagine a busy highway. Uniform lanes (consistent particle size) allow for smooth, fast traffic (lithium-ion flow). Now, imagine lanes that randomly narrow and widen (irregular particles). Traffic jams (ion bottlenecks), stress on the road (particle cracking), and inefficient use of space (incomplete material utilization) are inevitable. This is precisely what happens inside a battery.

How Precision Grading Directly Elevates Battery Performance:

Enhances Rate Capability & Power Density: Uniformly sized cathode particles, particularly those with a controlled narrow distribution, create homogenous pore networks. This facilitates faster and more uniform electrolyte penetration and lithium-ion diffusion, allowing the battery to charge faster and deliver higher bursts of power without excessive voltage drop.

Extends Cycle Life & Improves Stability: Oversized or agglomerated particles experience higher local stress during repeated lithium insertion/extraction (charging/discharging). This leads to micro-cracks, loss of electrical contact, and increased solid-electrolyte interphase (SEI) growth. By removing these outliers, precision grading ensures each particle expands and contracts uniformly, dramatically reducing structural degradation and capacity fade over hundreds of cycles.

Boosts Energy Density & Consistency: Tight control over the top cut (D97/D100)eliminates large, hard-to-lithiate particles. This maximizes the active material’s utilization in every gram of cathode paste. For cell manufacturers, this means more predictable and consistent capacity from batch to batch, enabling tighter BMS (Battery Management System) parameters and safer, more reliable battery packs.

the Epic Powder Advantage for Cathode Materials

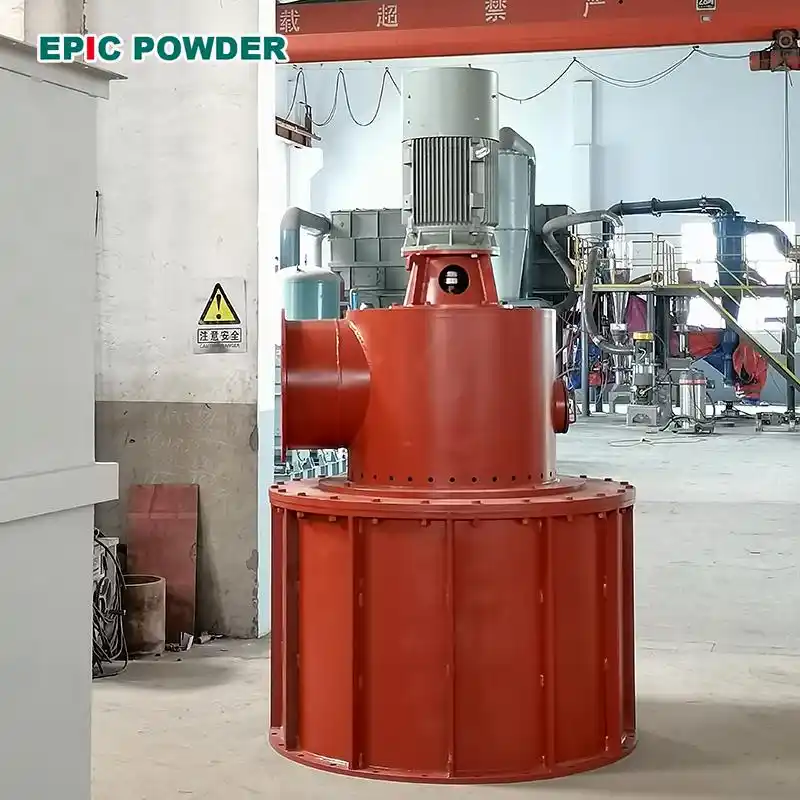

Moving beyond theory, Epic Powder’s advanced air classification technology provides the tangible control needed for next-generation batteries.

Our Technical Edge:

Sharp Cut Precision: Our classifiers achieve exceptionally steep cut curves, delivering the narrowest particle size distributions. This is crucial for high-Nickel (NMC, NCA) and Lithium Iron Phosphate (LFP) cathodes where consistency is non-negotiable. Unlike broad-separation methods, this precision ensures virtually no middlings or misplaced particles, maximizing your yield of in-spec material.

Ultra-Fine & High-Capacity Processing: We excel at efficiently separating fines in the sub-5µm range—a critical capability for enhancing tap density and coating quality without sacrificing performance.

Closed-Loop & Contamination-Free Design: Our systems are engineered to maintain material purity, preventing foreign element introduction that could jeopardize electrochemical stability. Robust designs minimize wear-particle generation, protecting your valuable cathode powder.

A Quantifiable Outcome:

A leading cathode producer faced challenges with the cycle life consistency of their material. By implementing an Epic Powder precision classifier to tightly control their D97 (< 8µm) and reduce fines, they achieved:

- A 15% reduction in capacity fade after 500 cycles.

- A 30% decrease in batch-to-batch variability for initial capacity.

- A direct improvement in their downstream electrode coating processability.

Conclusion: Partner for Peak Performance

In the race for longer-range EVs, longer-lasting electronics, and more efficient energy storage, granular control over powder properties is a decisive competitive advantage. It’s an investment that pays dividends in performance, safety, and brand reputation.

Ready to see the difference precision makes?

Schedule a free, confidential particle size analysis with our engineers. Send us a sample of your cathode powder, and we’ll provide a detailed report showing the potential performance gains achievable through Epic Powder’s precision battery powder classification technology.

Discover the Epic Powder advantage for your battery materials.

Contact our team today to discuss your project.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Jason Wang, Senior Engineer