Powder classification technology is a crucial component in the preparation and processing of powder materials, playing a vital role in their production. In recent years, with the advancement of modern high-tech and new materials industries, the fine powder industry has developed rapidly. The application of ultrafine powders has penetrated various domestic sectors. The demand for finer particle sizes and higher yields continues to grow. Achieving ultrafine classification of powder particles has become increasingly challenging. Traditional crushing methods can no longer produce qualified powders in a single step, making classification technology essential for separating products with the desired particle size. Thus, classification has become a key process in the mechanical preparation of fine powders.

Powder Classification Technology

Powder classification technology is a process that separates particle groups based on differences in physical characteristics. For example, they include particle size, density, and shape under specific force fields (e.g., centrifugal force, gravity, and inertial force). Its core objectives are to avoid over-crushing and improve product uniformity. It is widely used in industries such as chemicals, food, mineral processing, and pharmaceuticals. Depending on the medium used, it is divided into wet classification (water medium) and dry classification (air medium). Dry classification has become the mainstream technology due to its high efficiency and operational convenience.

Wet Classification

The primary medium used in wet classification equipment is water. The most significant advantage of hydraulic classification is its ability to promote particle dispersion. As the electrostatic and other interactive forces between particles are weakened in water, reducing agglomeration and resulting in better classification outcomes. However, it also has notable drawbacks: after classification, the particles are wetted by water and require subsequent solid-liquid separation and drying processes to obtain the final product. During these steps, re-agglomeration and caking of the powders are inevitable, increasing post-processing costs. Wet classification mainly takes two forms: gravity sedimentation and centrifugal classification.

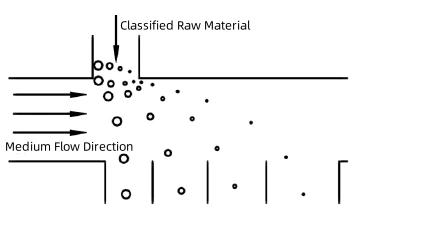

Gravity sedimentation-based wet classification relies on the differences in gravity and resistance for separation. In the classification equipment, the medium flows horizontally, and the powder to be classified enters the medium through the feed inlet. The particles disperse and settle continuously in the medium, with particles of different sizes or masses settling at varying rates. Simultaneously, the flow of the medium imparts a horizontal velocity to the particles. Particles of different sizes experience different horizontal forces, resulting in different horizontal velocities. Thus, particles of varying sizes follow distinct trajectories. When the particles settle at the bottom, they are distributed uniformly according to size. A multi-chamber structure at the bottom allows the raw material to be classified into several grades based on particle size, achieving a multi-level classification process.

Schematic Diagram of Gravity Sedimentation Classification

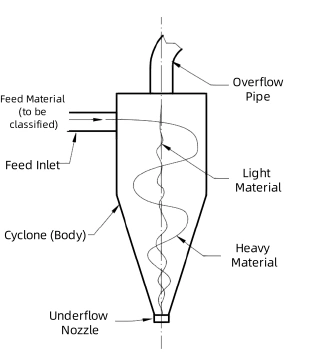

Centrifugal wet classification is a method that relies on the differences in centrifugal force experienced by particles of different sizes to achieve coarse and fine separation. The slurry particles to be classified are pumped into the cyclone chamber at a certain speed through the feed inlet along a tangential direction. Upon entering the chamber, the particles encounter the chamber wall and undergo rotational motion. Coarser and heavier particles, due to their larger mass and greater centrifugal force, move outward and accumulate along the periphery.

They then spiral downward along the conical chamber under gravity and eventually exit through the sand outlet. Finer particles, experiencing less centrifugal force, are hindered by the accumulating coarse particles before reaching the wall and remain near the center. This results in a uniform distribution from small particles at the center to coarse particles at the edge. It achieves classification by size with continuous feeding, coarse particles accumulate at the periphery. Fine particles near the center are squeezed and overflow through the upper outlet. It can successfully separating the fine particles.

Schematic Diagram of Hydrocyclone Working Principle

Dry Classification

Dry classification is a method that uses air as the medium. Since no water is involved, the classified powder does not require subsequent steps such as dehydration, drying, or dispersion. Currently, dry classification is the mainstream form of classification. Based on the types of forces acting on the particles during classification, dry classification can be divided into gravity classification, inertial classification, and centrifugal classification.

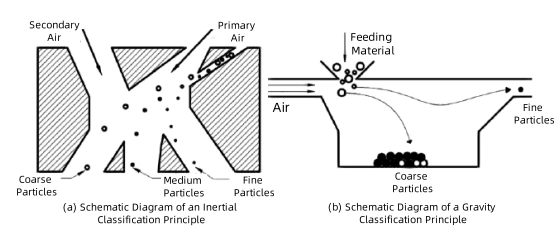

Gravity and inertial classification equipment come in various structural forms, but their principles are fundamentally similar: Inertial classification relies on the differences in inertia of particles of different masses, causing them to follow different trajectories within the equipment. Gravity classification achieves separation based on the varying settling speeds of particles of different masses under gravity, resulting in distinct motion paths.

Two Forms of Dry Classification

About Epic Powder

At Epic Powder, we specialize in advancing powder classification technologies to meet the evolving demands of modern industries. With a focus on innovation and efficiency, Epic Powder provides tailored classification systems. They cater to diverse applications, from pharmaceuticals and chemicals to mineral processing and beyond. Our commitment to excellence ensures that our clients achieve superior product quality and operational performance. Epic Powder, a trusted partner in the world of powder processing.