Printer toner plays a critical role in modern printing technologies such as laser printers, photocopiers, and multifunction devices. As the demand for superior print quality, sharper image resolution, and environmental compliance grows, advancements in toner manufacturing have become paramount. Central to these advancements are toner dispersion and sphericalization, which greatly influence toner performance and ultimately printing results. Air classifier mill represents a sophisticated and efficient methodology in printer toner dispersion.

The global printer toner market is projected to reach $15.2 billion by 2027, growing at a compound annual growth rate (CAGR) of 4.3%. This growth is largely driven by demand for higher print quality and more sustainable toner products.

What Is Printer Toner?

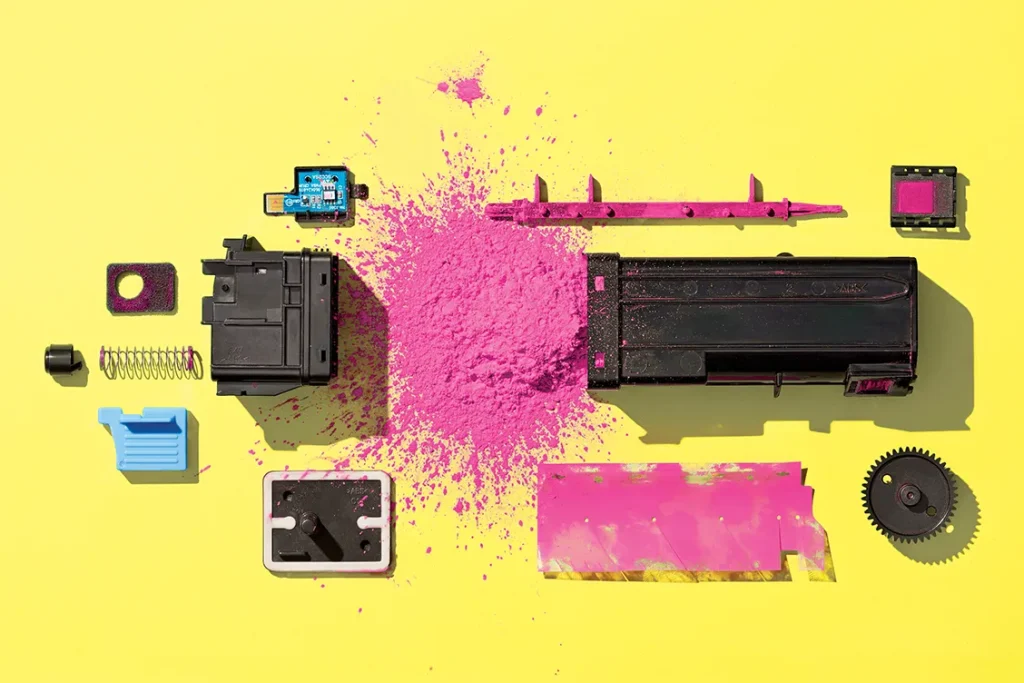

Printer toner is a finely divided powder used primarily in electrophotographic printing and copying. It consists chemically of polymer resin binders, pigments (commonly carbon black), charge control agents, and often waxes or other additives to improve fusing characteristics. The particles generally fall within a size range from submicron to about 10 microns.

The physical and electrical properties of toner particles are carefully engineered to ensure proper charging, transfer, and fixation during printing. Particle shape, size distribution, surface texture, and purity directly influence toner flow behavior, charge uniformity, and print quality. Traditionally, toners exhibited irregular morphologies and broad size distributions, issues that contributed to problems like clogging, inconsistent image reproduction, and lower efficiency. Modern developments emphasize producing spherical particles with narrow and tightly controlled size distributions to overcome these challenges.

Why Does Printer Toner Need Dispersion and Sphericalization?

Dispersion and sphericalization are integral steps in toner manufacturing as they dramatically enhance several property aspects essential for optimal printer function. Spherical particles exhibit superior flowability compared to irregularly shaped ones, facilitating consistent delivery and preventing feed blockages inside printers. Additionally, the uniform surface of spherical particles leads to more homogeneous triboelectric charge distribution, which improves toner transfer efficiency and reduces undesirable background noise or fog on prints. Spherical toner particles reduce friction by up to 30% compared to irregular shapes, enabling smoother feed mechanisms in printers. This translates into fewer misfeeds and less downtime.

Moreover, well-dispersed, spherical particles produce sharper images with fine details, minimal graininess, and precise edges, contributing to higher print resolution. The uniform melting and fusing behavior of spherical toner particles also enhance print durability, gloss, and resistance to smudging. Such shape and size control enable formulators to minimize the use of flow additives, simplifying toner composition and improving stability.

Collectively, these benefits make precise dispersion and sphericalization prerequisites for meeting demanding quality and environmental standards in today’s toner market.

Why Is Air Classifier Mill Used for Printer Toner?

Particle size is a critical parameter. Studies show that toners with median particle sizes (D50) between 6 to 8 microns deliver optimal flow and charging performance. Tight particle size distributions with span values below 1.5 correlate with improved print resolution and reduced background fog. Air classifier mills have become the technology of choice in toner processing. They uniquely integrate high-speed mechanical grinding with aerodynamic classification. This enables simultaneous size reduction and precise particle separation within a continuous operation. This integrated function is crucial for attaining the narrow size distributions and spherical morphologies demanded by modern toner formulations.

Unlike conventional mechanical milling methods, air classifier mills produce toner particles with uniformity and morphology. It’s controlled by modulating classifier wheel speeds and grinding parameters. Oversized particles are efficiently recycled through regrinding. Finer particles exit as the final product, forming a closed-loop that ensures consistency and minimizes material waste.

The milling action in air classifier mills combines impact forces with airflow dynamics. This improves the sphericalization of particles by breaking down agglomerates and sharp edges. It also keeps thermal generation low due to airflow cooling. This is vital for preserving polymer binder chemistry and preventing thermal degradation during processing. Additionally, the use of wear-resistant materials like ceramics and silicon carbide in critical components reduces contamination risks. It is essential for maintaining toner purity.

Furthermore, air classifier mills are capable of continuous high-throughput production. Air classifier milling can achieve throughput rates of 200 kg/h to over 1000 kg/h, supporting both pilot and large-scale production shifts without sacrificing quality. This advantage enables scale-up from research and development to full industrial manufacturing without compromising powder quality. This scalability, combined with fine particle control, makes air classifier milling well-suited to meet the rigorous demands of the toner industry.

Issues to Consider When Using Air Classifier Mill for Printer Toner

Despite the multitude of benefits, effective use of air classifier mills for toner production requires attentiveness to several vital factors. Achieving optimal outcomes depends largely on fine-tuning parameters such as rotor speed, classifier wheel speed, feed rate, and airflow volume. Inappropriate settings may cause over-grinding, generating excess fines or irregularly shaped particles, while under-processing can yield broad size distributions and insufficient sphericalization.

Consistent feed material quality and rate are equally important to maintain stable operating conditions and product uniformity. Fluctuations may disrupt classification efficiency and impair key functional properties.

Equipment wear is another key factor. Using ceramic or silicon carbide parts in milling reduces metal contamination to below 5 ppm, critical for color purity and electrical performance, especially in black and color toners. Wear and tear on critical components like classifier wheels, grinding anvils, and liners are inevitable, especially given the abrasive nature of pigmented toners. Therefore, choosing equipment with wear-resistant parts and instituting regular maintenance schedules are necessary to avoid contamination and unplanned downtime.

Temperature control during milling is vital. Although air classifier mills generate comparatively less heat than some alternatives, continuous temperature monitoring helps prevent degradation of the polymer binders and other sensitive ingredients. When air classifer mills maintain temperatures below 60°C, polymer binder degradation reduces by approximately 20%, helping maintain toner performance and shelf life.

Moisture sensitivity is also a concern because toner powders tend to agglomerate or lose charge uniformity in humid conditions. Maintaining low humidity within milling environments and utilizing dry, filtered air supplies can mitigate these issues effectively.

From a safety standpoint, powdered toner generates dust clouds that may be combustible. Thus, robust dust collection, proper ventilation, and adherence to safety protocols are paramount to protect personnel and equipment.

Lastly, thorough product testing encompassing particle size analysis, sphericity evaluation, charge stability, and flow behavior is essential to guide process adjustments and ensure batch-to-batch consistency.

Advantages and Disadvantages of Air Classifier Mill for Printer Toner

The major strength of air classifier mills lies in their ability to produce highly spherical toner particles with tight size distributions. It directly translates to improved toner flow, charging consistency, and print quality. The airflow-driven grinding reduces temperature rise, preserving binder integrity. The closed-loop system significantly diminishes contamination risks and facilitates continuous high-volume production. Moreover, integrating classification within the milling process streamlines operations by eliminating downstream classification steps.

However, these benefits come with some trade-offs. Air classifier mills tend to consume more energy than traditional mills when targeting extremely fine particle sizes. Wear on grinding and classification components leads to increased maintenance demands and associated costs. Operating the equipment effectively requires skilled personnel to ensure process parameters remain tightly controlled, preventing over-grinding or size distribution broadening. Additionally, the initial capital investment and system complexity are higher compared to simple conventional milling equipment.

Effects Achieved with the EPIC Powder Air Classifier Mill for Printer Toner

EPIC Powder Machinery’s air classifier mills are meticulously engineered to support toner production at the highest quality levels. Our equipment offers fine and reproducible adjustment of classifier wheel speeds and rotor configurations, enabling unparalleled control over toner particle size and shape. These capabilities produce uniformly spherical toner with narrow particle size distributions tailored to modern printing requirements.

Our designs incorporate efficient airflow and cooling, preventing excessive temperature elevation during processing and thereby protecting the delicate chemistry of toner binders. The use of premium wear-resistant ceramics and silicon carbide parts ensures long equipment life and maintains powder purity by minimizing contamination.

The continuous operation modes provided by EPIC mills allow seamless scaling from pilot studies to industrial manufacturing volumes without sacrificing consistency or quality. Furthermore, our readily accessible and modular components simplify maintenance, reduce downtime, and lower operational costs.

Clients utilizing EPIC Pair classifier milling solutions consistently report enhanced toner flowability, stable and uniform electrostatic charging behavior, sharper print resolution, and a reduction in printer malfunctions or defects. These improvements not only raise product competitiveness but also contribute to sustainable operation by minimizing waste.

Conclusion

Dispersion and sphericalization are foundational to producing printer toners that meet the stringent demands of today’s printing technologies. Air classifier milling represents a sophisticated and efficient methodology that balances precise particle size control, morphological uniformity, low-temperature processing, and high purity, all within a high-throughput, continuous process.

We invite you to partner with EPIC Powder Machinery to leverage our advanced air classifier milling technology combined with expert service support to elevate your toner manufacturing and capture market leadership.

For inquiries, technical consultations, or customized solutions, please contact our specialists. Together, we can drive innovation and excellence in printer toner production.

The Air Classifier Lab is a modern facility. It specializes in advanced particle size classification. This lab can achieve a particle size of D97: 2μm. It’s perfect for applications that need precise and fine material separation. The equipment can produce between 0.5 kg and 1 kg per hour. This makes it great for research and small-scale production. The Air Classifier Lab uses high-quality materials such as 304 stainless steel, alumina, and zirconia ceramic lining. This design ensures it’s durable and reliable for various processing settings. It also provides protective gas options like nitrogen and argon. These gases help improve the quality and purity of classified materials.