If you’re working with kaolin and wrestling with inconsistent particle sizes, you’re not alone. Achieving ultrafine precision, where every micron counts is a game-changer for industries like ceramics, coatings, and paper. That’s where kaolin air classifying steps in: a cutting-edge, energy-efficient process that transforms raw clay into perfectly sized powders with sharp d97 control, without the mess of wet classification. Ready to understand how Epic Powder’s air classifier delivers unmatched fineness and boosts your product’s performance? Let’s get into the science—and business—of precision kaolin refinement.

Understanding Kaolin: Properties and Why Classification Matters

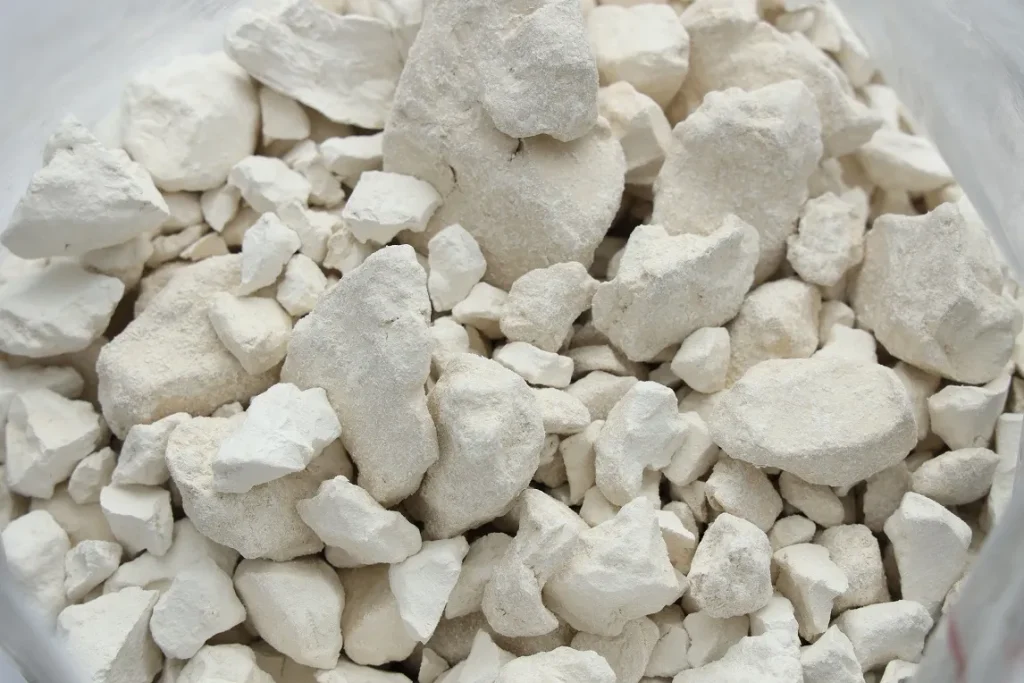

Kaolin, a fine white clay, is prized for its smooth texture, chemical inertness, and high brightness. Its core attributes include excellent whiteness, low abrasiveness, and fine particle size. However, raw kaolin often contains a broad range of particle sizes and impurities, posing challenges for consistent product quality.

Effective kaolin particle classification is essential. Proper sorting optimizes particle size distribution (PSD), separates fines and coarse particles, and enhances performance tailored to end-use demands. Control over key metrics like D97 micron size directly affects processing efficiency in ceramics, paper, and coatings.

Without precise classification, product inconsistency and poor dispersion can result. That’s why dry classifying kaolin processes, such as centrifugal air separation, are critical to refining particle sizes for ultrafine kaolin powder production. By mastering classification, manufacturers unlock kaolin’s full potential across industries.

How does your current process handle kaolin PSD optimization, and are you seeing the quality consistency you need?

The Science of Air Classifying: Mechanics and Technology Breakdown

Air classifying relies on the smart use of airflow and centrifugal force to separate kaolin powder by particle size without using water. The principle is simple but effective: a high-speed turbine generates a strong airflow inside the classifier, pushing finer particles upward with the air stream while heavier, coarser particles drop down due to gravity and centrifugal force.

Here’s how it works in practice:

Centrifugal separation: The turbine spins rapidly, creating a vortex that forces larger kaolin fines and coarse particles outward and downward.

Airflow control: Adjusting the air velocity allows precise control over the particle size cutoff, enabling strict D97 micron control and optimal kaolin PSD optimization.

Process flow: Raw kaolin feeds into the classifier, where it first encounters a pre-classification area. Fines are carried away by airflow, while coarse fractions are collected separately.

Compared to traditional wet classification methods, air classifying offers several clear advantages:

It eliminates the use of water, reducing drying costs and wastewater treatment.

The dry classifying kaolin process is energy-efficient, minimizing operational expenses.

It produces ultrafine kaolin powder consistently with high throughput capacities, enhancing overall productivity.

Recent technology innovations, such as improved turbine air classifier specifications and modular designs, have further streamlined this process, making air classification the go-to choice for industrial kaolin milling equipment. For a deeper dive into these mechanics, check out detailed insights on air classification technology and equipment and the working principle of turbo air classifiers.

Epic Powder’s HTS 315: Specifications and Real-World Performance

Epic Powder’s HTS 315 air classifier is designed for efficient kaolin particle classification, combining high throughput with precise control over powder quality. Its modular design allows users to scale capacity and customize features, making it a flexible choice for a range of industrial needs.

Key Specifications of HTS 315

| Parameter | Value |

| Feed Size | 400 mesh |

| Fine Powder Output (D97) | 5.80 µm |

| Coarse Powder Output (D50) | 15.20 µm |

| Throughput Capacity | 500 kg/h |

| Model | HTS 315 |

This model excels in producing ultrafine kaolin powder with tight particle size distribution (PSD), crucial for industries requiring D97 micron control in minerals. Its turbine air classifier system uses centrifugal air separation for reliable separation of kaolin fines and coarse particles, all without using water, ensuring an energy-efficient and dry classifying kaolin process.

Real-World Application and Customization

A typical case involves a ceramics manufacturer adjusting their kaolin grade for better coating performance. Using the HTS 315, they achieved consistent feed size reduction to ultrafine levels while maintaining a steady output of 500 kg/h. The modular setup enabled them to integrate upgrades smoothly, tailoring the system to evolving PSD requirements.

For those interested in deeper technical details or installation options, Epic Powder offers comprehensive customization. Check out the detailed HTS series air classifier specs for a complete overview of performance and scalability.

This flexible approach not only optimizes particle quality but also supports industrial goals like sustainability and process efficiency.

Applications: Tailoring Classified Kaolin for Industry Demands

Classified kaolin finds broad use across many industries thanks to its controlled particle size distribution (PSD) and purity. In ceramics, ultrafine kaolin improves whiteness, strength, and surface finish. For paper production, it enhances brightness, opacity, and printability by filling the fine spaces between fibers. In paints and coatings, kaolin acts as a sustainable extender that improves durability and texture without adding weight. The cosmetics industry relies on finely classified kaolin for its smooth feel, oil absorption, and gentle nature on skin, making it ideal for powders and creams.

Emerging uses span from rubber fillers to pharmaceuticals, where precise PSD control is critical. To give a quick overview, the table below compares kaolin particle size requirements across industries:

| Industry | Key PSD Targets | Typical Particle Size (Μm) |

| Ceramics | High whiteness, smoothness | D97 ≈ 5-7 |

| Paper | Opacity and brightness | D50 ≈ 2-10 |

| Paints & Coatings | Durable texture | D50 ≈ 6-15 |

| Cosmetics | Soft feel, oil absorption | D97 ≈ 3-7 |

| Emerging Fields | Specialized blends | Customized PSD |

Customizing your kaolin’s PSD through air classification ensures you meet precise industry specs consistently. For example, our air classifiers provide excellent control over D97 micron targets, critical for high-end ceramics and cosmetics. Explore the strategic applications of kaolin to see how tailored kaolin solutions create value in multiple sectors. You can also check how air classification impacts kaolin’s cosmetic applications from powder behavior to final use.

With precise air classifying tech, achieving the right balance between fines and coarse particles becomes simple, unlocking kaolin’s full potential across industries.

Benefits of Epic Powder’s Air Classifying Approach: Efficiency, Sustainability, and ROI

Epic Powder’s air classifying technology offers clear advantages in processing kaolin, boosting both efficiency and sustainability while delivering solid returns on investment.

Operational and Sustainability Advantages

Energy-efficient kaolin refining: The dry classifying kaolin process reduces energy use compared to wet methods, cutting costs and environmental impact.

Precise particle size control: With D97 micron control in minerals, especially for ultrafine kaolin powder production, Epic Powder ensures consistent quality for diverse applications.

Less water usage: The centrifugal air separation kaolin approach lowers water consumption, supporting sustainable mineral processing.

Easy cleanup and low maintenance: Modular design means minimal downtime and simpler upkeep, increasing operational uptime.

Economic and Safety Compliance Benefits

| Benefit | Description |

| High throughput (500kg/h) | Supports large-scale production with low overhead |

| Reduced waste | Accurate kaolin fines and coarse separation improve yield |

| Compliance with safety standards | Dry process cuts risks linked to slurry handling |

| Lower operating costs | Less energy and water consumption save expenses |

User Testimonials

Many Epic Powder customers praise the HTS 315’s reliability and consistency:

“Since switching to Epic Powder’s air classifier, our kaolin particle classification has improved, saving energy while raising product quality.”

— Industrial mineral processor

By combining efficiency, sustainability, and economic benefits, Epic Powder’s air classifying approach proves to be a smart choice for industrial kaolin milling equipment users worldwide.

For a closer look at the technology behind efficient powder processing, you can explore the details of air classifying grinding techniques similar to those used in our systems.

Implementation Guide: Optimizing Kaolin Air Classifying in Your Operation

Getting your kaolin air classifying process right starts with a thorough site assessment. Ensure your workspace has adequate ventilation, stable power supply, and enough room for the HTS 315 model and any ancillary equipment. Proper installation isn’t just about fitting the machine—it’s about aligning the classifier with your existing production line for smooth feed handling and powder collection.

Installation Best Practices:

Position the air classifier to minimize material transfer distance and dust exposure.

Seal all ducting and connections to maintain airflow efficiency.

Calibrate the turbine air classifier specifications based on your feed size (up to 400 mesh) and desired particle size distribution (D97 = 5.80 µm for fine powder).

Verify that all safety safeguards and monitoring systems are in place before starting operations.

Troubleshooting Tips:

If output particle size deviates, re-check airflow settings and rotor speed.

Monitor feed consistency—irregularities can affect classification efficiency.

Regularly clean classifier components to prevent build-up impacting centrifugal air separation kaolin performance.

Use real-time data on feed rate and powder quality to fine-tune operations.

Epic Powder

HTS 315 by Epic Powder offers modular scalability—add units or sections as your production volume grows.

Optimize kaolin PSD by adjusting classifier parameters, boosting yield without sacrificing qualitykkko.

Consult with Epic Powder for custom modifications tailored toward high-throughput powder classifier needs.

For operators aiming to streamline kaolin particle classification, access to a free process simulation can help model your production line and predict outcomes before installation. Epic Powder offers these simulations to make implementation smoother and more cost-effective. Explore more about optimal operation at this guide on finding the best fit for your powder processing needs.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Jason Wang, Senior Engineer