Designing a pneumatic conveying and feeding system in an air classifier mill for powdered calcium carbonate in plastics compounding operations requires a comprehensive understanding of powder behavior, flow properties, and process equipment. A poorly designed system can lead to material buildup, inconsistent feed rates, and product quality issues.

This article presents a full technical guide on how to design an effective conveying and feeding system that integrates seamlessly with equipment like an air classifier mill, optimizing performance, efficiency, and product consistency.

Why Calcium Carbonate?

Calcium carbonate is one of the most widely used mineral fillers in the plastics industry, valued for its versatility, cost-effectiveness, and ease of processing. It is compatible with various polymer resins and can be finely ground to a targeted particle size for optimal performance. As an additive in plastic composites, calcium carbonate reduces surface energy, enhances opacity and gloss, and contributes to a smoother surface finish. When particle size is carefully controlled, it can also improve impact strength and flexural modulus (stiffness).

Calcium carbonate is suitable for a wide range of thermoplastics. In polypropylene composites, it increases hardness—crucial for high-temperature applications. In PVC, it is used in both flexible products (e.g., pipes, wire and cable insulation, latex gloves, garbage bags) and rigid applications (e.g., extruded pipes, water pipes, door and window profiles).

Pneumatic Conveying Systems for Calcium Carbonate

The particle shape, size (aspect ratio), size distribution, as well as surface roughness, hardness (abrasion resistance), and bulk density of solids play a critical role in the design of feeding and pneumatic conveying systems.

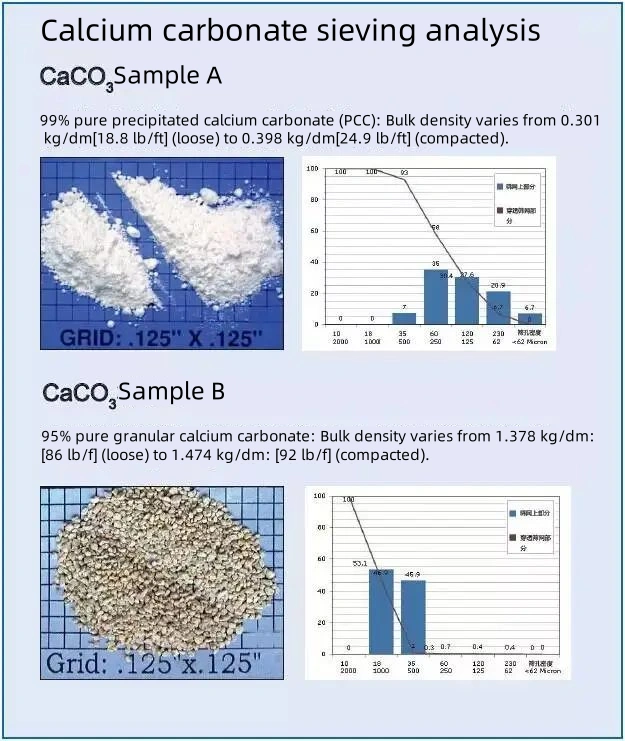

In the case of calcium carbonate, its physical properties can vary greatly depending on the source and manufacturing process. As shown in Figure 1, sieve analysis reveals notable differences in particle shape, size, and distributionbetween two distinct samples.

Figure 1

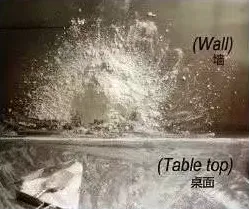

Due to the complex particle interactions (as illustrated in Figure 2), establishing a direct correlation between a filler’s particle-level properties and its bulk flowability is challenging. As a result, pneumatic conveying systemscannot be standardized or purchased off-the-shelf—they must be custom-designed for each specific application. Variations in bulk characteristics directly impact system design and equipment selection, making laboratory testingessential to accurately assess material properties and flow behavior.

Particle Interactions

Three key types of interactions influence the flow behavior of mineral fillers in pneumatic conveying and feeding systems: particle-particle, particle-equipment, and particle-environment interactions.

Particle–Particle Interactions

These interactions are governed by the chemical composition and physical properties of the filler, independent of bulk behavior.

The primary forces at play are electrostatic forces and van der Waals forcesbetween particles. Van der Waals forces weaken with increasing particle separation, meaning the addition of finer particles to cohesive powders can sometimes improve flowability.

Other relevant forces include:Capillary forces, which arise from liquid bridges when water vapor is present in the surrounding gas. Sintering forces, which cause solid bridging due to material migration through diffusion or viscous flow. These interparticle forces can lead to increased cohesion, promoting agglomeration and reducing flow efficiency.

Particle–Equipment Interactions

The movement of solid particles through hoppers, pipes, or other containers depends largely on two material properties:

Wall friction, which describes how particles slide against the equipment surfaces. Shear strength, which refers to the resistance of a compacted powder mass to deformation or internal particle movement. Both properties are critical for reliable feeding and conveying performance.

Particle–Environment Interactions

External factors—such as temperature, relative humidity, vibration, gravity, and air flow—also impact powder flow. Humidity influences capillary forces via moisture adsorption and liquid bridge formation, particularly in hygroscopic materials.

Temperature affects crystallinity and can promote sintering, altering particle structure and flowability. Pressure increases interparticle contact, leading to higher packing densityand stronger adhesion. Together, these environmental conditions shape the overall flow characteristics of the bulk material.

Pneumatic Conveying Systems for Calcium Carbonate

A pneumatic conveying system typically consists of five basic components: a power unit, a conveying line, a batching unit, a material-gas separation unit, and a control system.

Batching Equipment

When selecting a batching unit, it is essential to consider that certain calcium carbonate particle sizes are lightweight and highly free-flowing, which may result in excessive material entering the conveying line. To control the feed rate, a rotary valve is often used to meter material into the pneumatic conveying system—whether it operates under pressure or vacuum.

However, due to calcium carbonate’s varying cohesiveness, material buildup on the vanes of a drop-through rotary valve can occur. In such cases, a blow-through rotary valve is recommended. This type of valve uses air jets to clear material from the vanes as it rotates, preventing accumulation. Additionally, installing a fluidizing cone at the bottom of the feed silo can further enhance flow control by promoting consistent material discharge.

Conveyor Lines

Calcium carbonate powder can cause numerous problems in air classifier mill conveyor systems. The problems include material getting stuck in the hopper, flooding the conveyor line, accumulating inside the conveyor line, and clogging filter bags or silos in the receiving unit.

Rigid tubing can be used as conveyor lines for both highly fluidized and slightly sticky calcium carbonate. However, if the calcium carbonate tends to adhere to the inside of the conveyor line, consider using flexible tubing. Its flexible nature prevents buildup on the pipe walls.

In continuous vacuum systems, using flushing valves is a good way to ensure that the conveyor line remains clean between transfers. First, close the shutoff valve on the feed side of the vacuum system to increase the air pressure in the conveyor line. Then, open the valve, the resulting pressure wave will help clear any material adhering to the inner surfaces of the conveyor line.

Material Gas Separation Units

Calcium carbonate tends to adhere to filters, causing blockage and reducing filter efficiency. For sticky calcium carbonate, using filter bags instead of pleated filter cartridges can help prevent calcium carbonate from adhering to the filter. In severe cases, using PTFE filter media is recommended. Some calcium carbonate may require a steeper, more tapered discharge to help completely discharge the hopper. Flow aids, such as vibrators or fluidizing pads within the receiver hopper, often ensure faster and more complete discharge.

Calcium Carbonate Feeding

Two primary variables determine the selection of an air classifier mill feed system for each calcium carbonate sample: the characteristics of the mineral filler (e.g., particle size and shape, gas permeability, bulk density, and angle of repose) and the desired feed rate.

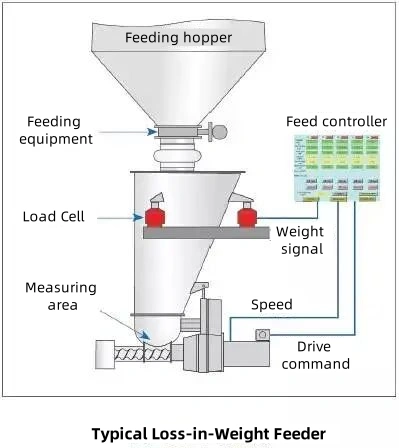

Loss-in-weight (LIW) feeders offer fully enclosed material handling, minimizing dust and ensuring precise feed rates to maintain final product quality. These feeders come in various configurations, allowing customization of hopper size, feeding mechanisms, and weighing systems to match specific material characteristics, flow behavior, and required feed rates.

Volumetric Measurement vs. Gravimetric Measurement

Most feeders can be categorized as either volumetric or gravimetric.

Volumetric feeders deliver a constant volume of material per unit time and offer the lowest capital cost feeding solution. However, screw-type volumetric feeders lack detection capabilities and cannot adjust for changes in bulk density. Therefore, these feeders are best suited for relatively free-flowing materials with stable bulk density (e.g., pellets) and applications where feeding accuracy is not critical.

Gravimetric feeders deliver a constant weight of material per unit time. Gravimetric feeders not only monitor the feeding process but also have a feedback loop that measures weight and speed to determine the actual weight fed per second.

Hopper Selection

Once the size and type of feeder have been determined, a hopper of the appropriate shape and size must be selected to hold the material required for continuous plastic compounding operations.

Hoppers are available in cylindrical, asymmetric, and symmetric shapes, ranging in size from one liter to several hundred liters. The size of the feeder hopper depends on the feeder’s refill requirements and the available space. Usually, if we refill the hopper 12 times per hour, the maximum fill level should be 80% of the hopper volume. Hopper size should not be excessive due to incremental cost and space requirements. The potential for increased material compaction is due to particle interaction. Therefore, the following theoretical calculation method can be used to provide a preliminary estimate of the hopper size: Hopper capacity = flow rate / (bulk density × 0.8 × 12).

Precipitated calcium carbonate in the hopper tends to become compact. It can lead to ratholes and bridging.

Feeding Equipment

The feeding equipment used varies depending on the material being fed.

Single-screw feeders can be used for easy-flowing powders and granules. Twin-screw feeders for difficult-flowing powders, and vibratory trays for fibrous and friable materials.

Twin screw design

For free-flowing calcium carbonate, a single screw feeder is sufficient. A twin-screw feeder is generally recommended for more reliable results. A variety of screw types can be used, depending on the flow rate and characteristics of the mineral filler. The most commonly used screw profiles are concave, drill, spiral, and twin-screw. The purpose of a screw is to uniformly feed large amounts of solids into the plastic compounding process. These screws can also block material flow when the screw feeder stops, preventing a large influx of fluidized solids.

Calcium carbonate also tends to compact on metal surfaces, such as feeder screws. To address this, two intermeshing, co-rotating screws with self-cleaning features are used to ensure clean screw surfaces and a buildup-free environment.

Bridge Scales

Weighing systems ensure consistent, controlled feeding into the classifier mill. The options range from small-capacity platform scales to large three-point suspension systems. Integration with feeders allows precise control of feed rate and ensures final product quality

Conclusion

From particle behavior to equipment design, conveying and feeding powdered calcium carbonate into an air classifier mill requires careful consideration of material science and mechanical engineering. By optimizing each component like conveying lines, feeders, hoppers, and weighing systems, it ensures high product consistency, minimized downtime, and efficient filler modification.

About EPIC Powder Machinery

At EPIC Powder Machinery, we provide advanced systems for ultrafine grinding, pneumatic conveying, and air classification. Our customized solutions, including high-performance air classifier mills, are trusted for processing calcium carbonate and other challenging mineral fillers in plastics, coatings, and chemical industries. Let our experts help you design the ideal system for your application.

Contact us today to learn more.