Introduction: The Rise of the Feline Empire

Let’s face it: cats are not just pets anymore—they are family. In fact, in many households, they are royalty. Over the past decade, the global pet industry has seen a massive boom, with cats taking a comfortable seat (usually your laptop keyboard) in millions of homes. According to the International Pet Federation, the number of households owning cats has increased by over 35% globally since 2015. Why? Well, cats are cute, independent, and don’t judge you for binge-watching 12 episodes of a drama at 3 AM. But there’s a catch: they are also extremely picky about where they do their business. Welcome to the high-stakes world of cat litter, where texture, odor control, and clumping ability can make or break a product. One of the most popular and effective materials? Bentonite cat litter.

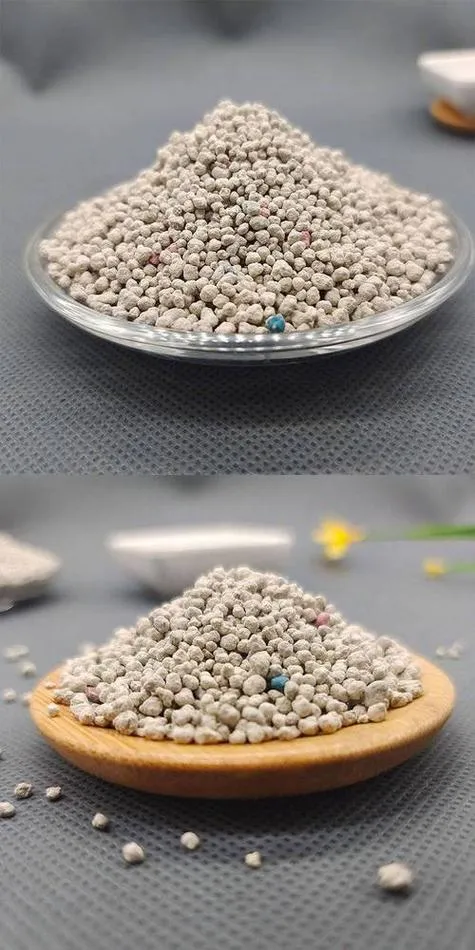

What Makes Bentonite the King of Cat Litters?

Bentonite is a naturally occurring clay, rich in montmorillonite, that expands and forms gels when in contact with water. This property makes it an ideal ingredient in cat litter for its superior clumping and absorbent characteristics.

Here are a few reasons why bentonite is favored:

High Absorption Rate – Up to 500% of its own weight in water.

Strong Clumping Ability – Easy to scoop and manage.

Odor Control – Traps ammonia and other unpleasant smells.

Non-toxic & Safe – Doesn’t pose a risk to cats if used properly.

However, not all bentonite is created equal. The performance of bentonite cat litter depends heavily on particle size, distribution, and surface area—all of which are determined by the grinding and classification process.

That’s where EPIC Powder Machinery comes in.

Section 1: Raw Bentonite—From Quarry to Processing Plant

Bentonite is usually extracted from open-pit mines, dried under natural sunlight or in rotary dryers, and then transported for processing. But raw bentonite is just the beginning. The magic happens during milling and classification.

Key Challenges in Bentonite Cat Litter Processing:

Achieving the ideal particle size for quick clumping and good fluidity.

Ensuring low dust levels — nobody wants a mini dust storm every time the cat jumps in.

Retaining moisture-absorption capabilities even after grinding.

Maintaining material purity (some additives or contaminants can irritate a cat’s nose or paws).

Section 2: Enter the Hero – The air Classifier

At EPIC Powder Machinery, we’ve developed and supplied advanced air classifier mills specifically optimized for mineral applications like bentonite.

Our equipment combines ultrafine grinding with precise classification, ensuring that every granule of bentonite behaves like a well-trained cat: clean, compact, and consistent.

Why Air Classifier Works for Bentonite:

Unlike simple crushers or traditional mills, our classifying mill integrates a classifier wheel that sorts particles in real-time as they’re being ground. This helps:

Achieve narrow particle size distribution (PSD).

Reduce over-grinding (which causes dust and lowers absorption).

Enhance product performance for final cat litter formulations.

Let’s break it down:

| Parameter | Target for Bentonite Cat Litter |

| Particle Size (D50) | 80–200 µm |

| Clumping Time | < 2 seconds |

| Moisture Absorption | ≥ 300% |

| Bulk Density | 0.7–0.9 g/cm³ |

| Dust Level (PM10) | < 1% |

| Montmorillonite Purity | 85% |

Section 3: The EPIC System in Action – Process Flow Overview

Let’s follow the path of a bentonite particle through an EPIC Powder air classifier mill system.

Step-by-Step Flow:

1. Feeding System

Bentonite lumps are fed via a screw conveyor or vibrating feeder into the primary crusher.

2. Primary Crushing

Large chunks are broken down to manageable granules (~5 – 10 mm).

3. Drying Stage (optional based on moisture content)

Our system can integrate an inline dryer to ensure input materials are moisture-stable for grinding.

4. Air Classifer Mill

This is where the action happens:

High-speed rotor crushes the particles.

The built-in classifier ensures only particles of the desired size exit the system.

Oversized particles are sent back for re-grinding.

5. Dust Collection

With our pulse bag dust collector, air is cleaned to meet environmental emissions standards (EU, EPA), and the plant stays clean— just like a cat’s litter box should be.

6. Product Storage & Packaging

Final product is stored in silos or packed directly into 5–50 kg bags via automated packaging lines.

Section 4: Some Data to Litter-ally Prove Our Results

Here’s performance data from a recent project we delivered for a cat litter manufacturer in Eastern Europe:

| Parameter | Before EPIC System | After EPIC System |

| Particle Size D50 | 280 µm | 120 µm |

| Dust Content (PM10) | 5.2% | 0.6% |

| Clump Cohesion Rating (1–5) | 2.8 | 4.7 |

| Odor Control Efficiency | Medium | High |

| Throughput (tons/hour) | 1.2 | 3.0 |

In short: finer, cleaner, stronger clumps — and happier customers.

Section 5: A Word on Customization – Because No Two Litters Are the Same

Just like cats have personalities (and attitudes), every cat litter brand wants to stand out. That’s why we provide tailored solutions:

Adjustable classifier speeds for different fineness needs.

Integration with odor-absorbing additives or colorants.

Specialized designs for scented or natural organic cat litter lines.

Our air classifier mills can be combined with spray coating units, blenders, and bulk handling systems to deliver a complete, turnkey solution.

Section 6: But Wait — What About the Cats?

In all our technical talk, let’s not forget the end-user: the cat.

From a feline’s perspective, the ideal litter is:

Soft on the paws (optimized grain shape)

Quick to clump (immediate feedback matters!)

Low in dust (cats hate sneezing too)

Free of irritating scents or chemicals

With EPIC’s finely tuned grinding and classification, we deliver litter that passes the paw test—time and again.

Section 7: Sustainability & the Future of Cat Litter

While bentonite remains the king of clumping litters, the market is shifting toward eco-friendly options—such as:

Tofu-based litters

Wood or paper-based litters

Cornstarch formulations

We at EPIC Powder Machinery are already developing new systems for grinding and classifying plant-based materials, with the same precision and cleanliness as we’ve achieved for bentonite.

Section 8: Final Thoughts – From Quarry to Kitty

To the untrained eye, cat litter might seem like a simple product.

But those of us in the materials processing industry know the science, precision, and technology required to deliver a product that both cats and their humans appreciate.

At EPIC Powder Machinery, we’re proud to serve this growing market with the world’s leading ultrafine grinding and classification systems—because every cat deserves a throne made of perfect powder.

About EPIC Powder Machinery

We specialize in ultrafine powder solutions for the chemical, mineral, food, and new material industries. With decades of experience and European core technologies, we deliver precision grinding, classification, and turnkey powder processing systems for global clients.

Want to upgrade your production line for cat litter or other bentonite applications? Let’s talk.

Contact us at: mineral@epic-powder.com

Visit: powder-air-classifier.com

Follow us on LinkedIn for more insights!

https://www.linkedin.com/feed/update/urn:li:activity:7339194295444230144