In industrial powder processing and mineral separation applications, selecting the appropriate classification equipment is crucial for achieving optimal product quality and production efficiency. Single spiral classifiers and air classifiers represent two fundamentally different approaches to particle separation, each with distinct advantages tailored to specific material characteristics and industry requirements. Single spiral classifiers and air classifiers differ significantly in terms of working principles, structural composition, particle size range, application scenarios, operation and maintenance, as well as energy efficiency and environmental impact. Understanding these key differences enables manufacturers and processors to make informed decisions when selecting classification equipment for their particular operational needs.

Working Principles

Single Spiral Classifier:

Operates based on the differences in settling velocity of solid particles in liquid. Fine particles, with slower settling rates, remain suspended and are discharged through the overflow port, while coarse particles settle at the bottom and are pushed toward the discharge port by the spiral blades. The core principle combines gravity sedimentation and mechanical conveying.

Air Classifier:

Utilizes the movement characteristics of particles in an air stream for classification. Fine particles, due to their low mass and weak inertia, follow the airflow and are collected through the gaps in the classification rotor. Coarse particles, with higher mass and stronger inertia, collide with the chamber wall and settle for discharge. The core principle relies on the dynamic balance between centrifugal force and air drag.

Structural Composition

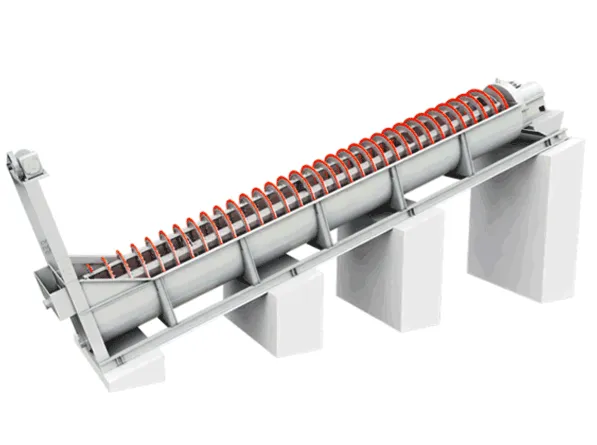

Single Spiral Classifier:

Main Structure: Consists of a tank, spiral blades, transmission device, and lifting mechanism.

Key Components: The spiral blades serve as the core for classification, enabling particle separation and transport through rotation. The tank provides a stable settling space for efficient grading.

Air Classifier:

Main Structure: Comprises a classification rotor, drive motor, cyclone separator, dust collector, and exhaust fan.

Key Components: The classification rotor generates a centrifugal force field via high-speed rotation, while the cyclone separator and dust collector ensure particle collection and air purification.

Particle Size Range

Single Spiral Classifier:

Suitable for coarse particle classification, typically handling sizes above 0.15mm. For example, high-weir classifiers usually process overflow particles larger than 0.15mm, while submerged types can handle finer particles but are primarily designed for coarse grading.

Air Classifier:

Ideal for micron-level fine classification, achieving adjustable particle sizes of D97: 3–150 microns, meeting high-precision grading requirements.

Application Scenarios

Single Spiral Classifier:

Metal Mining: Works in a closed circuit with ball mills to separate ore sand, remove slime, and improve mineral processing efficiency. For example, it helps eliminate impurities in iron ore processing and ensures gold purity in gold ore beneficiation.

Non-Metallic Fields: Used in quartz sand production to control powder content (adjustable between 2%-15% for 0.00-0.75mm particles).

Air Classifier:

Chemical & New Materials: Processes non-metallic minerals like calcium carbonate, kaolin, and quartz, as well as powders in pharmaceuticals, pesticides, and food industries.

Environmental & Solid Waste Treatment: Recycles construction waste and solid residues, enabling resource recovery and eco-friendly disposal.

Operation & Maintenance

Single Spiral Classifier:

Operation: Requires uniform feeding to prevent clogging; periodic adjustment of parameters (e.g., blade angle, water flow rate) optimizes performance.

Maintenance: Inspect spiral blade wear and replace damaged parts; clean the feed inlet and tank to avoid impurity buildup.

Air Classifier:

Operation: Maintain stable airflow velocity; adjust rotor speed for precise particle size control.

Maintenance: Regularly check rotor and bearing wear, apply lubricants; clean dust collector filters to ensure air purification efficiency.

Energy Efficiency & Environmental Impact

Single Spiral Classifier:

Energy Consumption: Relies on mechanical transmission, consuming relatively low power, but energy use rises significantly with larger processing volumes.

Environmental Impact: Requires substantial water, potentially causing wastewater pollution. While optimized designs reduce discharge, its eco-friendliness remains limited.

Air Classifier:

Energy Consumption: Equipped with high-efficiency motors and frequency control for lower energy use. Multi-stage air classifiers further enhance efficiency.

Environmental Impact: Dry processing eliminates water waste and wastewater discharge. The negative-pressure system minimizes dust emissions (<40mg/m³), complying with environmental standards.

Epic Powder

Epic Powder is a leading manufacturer of advanced powder processing and classification equipment, specializing in air classifiers, grinding mills, and related industrial solutions. Committed to innovation and sustainability, we provide high-performance, energy-efficient systems tailored for industries such as mining, chemicals, pharmaceuticals, and environmental protection. Our cutting-edge technology ensures precise particle control, reduced operational costs, and eco-friendly production, making us a trusted partner in global powder processing applications. Contact Us Today for Your Customized Powder Classification Solution.