What is Powder Classification?

Powder classification refers to the process of separating a group of particles into two or more size categories based on differences in settling velocity within the same medium. These differences arise from variations in particle size, density, shape, or surface physicochemical properties. The key aspects of powder classification technology are dispersion and separation. Producing particles that meet industrial production requirements through powder classification is a crucial step in powder processing.

Based on the medium used, classification can be divided into wet and dry methods. Wet classification typically uses water or other liquid phases as the medium. However, challenges such as drying the classified products and handling the medium often increase separation difficulty, add to the workload, reduce classification efficiency, and ultimately limit the widespread adoption and application of wet classification. In contrast, dry classification generally uses air as the medium and employs centrifugal or inertial force fields to classify powders. Due to its simple operation and high separation efficiency, dry classification has become the preferred method for rapidly developing fine classification equipment.

Air Classifier: Mainstream Dry Classification Equipment

Air classifiers have a history of over a hundred years. In recent years, significant advancements in fine powder technology have led to the development and widespread application of various new and highly efficient air classification devices. However, in terms of working principles, the evolution of air classifiers can be summarized into three generations: first-generation centrifugal air classifiers, second-generation cyclone air classifiers, and third-generation turbo air classifiers. Among these, vortex air classifiers are widely used across various industries due to their simple structure, adjustable operational parameters, and broad, customizable range of fine powder particle sizes. They have become the mainstream dynamic classification equipment today.

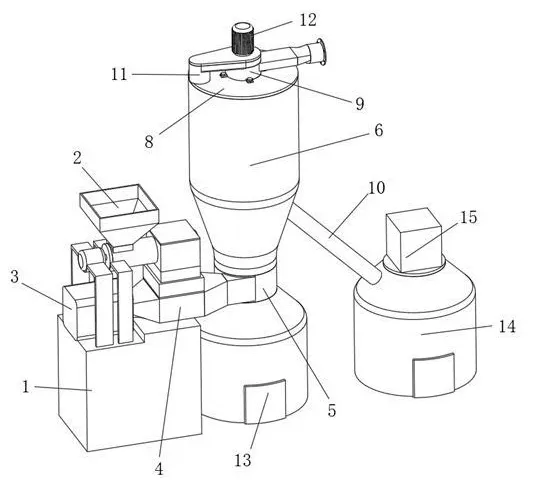

The turbo air classifier generally consists of key components such as a volute, rotating cage, conical barrel, guide vanes, and a dispersion disc.

Structure of the Turbo Air Classifier

Typically, airflow enters tangentially through two inlet ports into the volute of the turbo classifier. The airflow passes through guide vanes in the spiral volute. It then enters the classifier’s annular region. Fan suction creates negative pressure at the cage center. This gives the airflow both tangential and radial velocity. The radial velocity moves toward the axis. Most airflow enters the rotating cage. It makes a 90° turn at the center. Then it exits axially through the discharge pipe. Material enters from the top inlet. It lands on the dispersion disc for scattering. Then it enters the annular region by gravity. Negative pressure pulls particles toward the cage’s edge.

Particles experience gravity and centrifugal force. They also feel inward drag from the airflow. These forces together achieve classification. Fine particles exit with the airflow. They leave through the fine powder outlet. A powder collector gathers them. Coarse particles hit the volute wall. They spin downward while descending. Then they fall into the conical discharge hopper. Finally, they exit through the coarse powder outlet.

Classification of Turbo Air Classifiers

Research Progress on Turbo Air Classifiers

Turbo air classifiers’ performance depends on structural and operational factors. Key structural parameters include the rotating cage design. This includes blade number, diameter, shape, and angle. Guide vane structure is also critical. It involves vane count, diameters, shape, and installation. The dispersion disc’s height, diameter, and shape matter too. Other factors are annular region design and secondary air inlets. Operational parameters include feed rate and air inflow. Air volume and velocity are also important. The industry continuously addresses challenges like powder agglomeration. It seeks to meet various classification requirements. Products need different grades and applications.

About Epic Powder

Epic Powder specializes in this advanced technology. Vortex airflow classification offers simple operation and high precision. It is ideal for large-scale production. This technology is highly competitive in ultrafine powder preparation. To enhance classification accuracy, improvements are needed. Better efficiency meets growing industry demands. Advancements focus on ultrafine classification capabilities. Multi-grade product classification requires development. Multi-purpose applications need further exploration. Deagglomeration of powders remains crucial. Continued research and development are essential. Epic Powder supports these technological advances. The company drives innovation in powder processing. Future breakthroughs will shape the industry.