The optimal operating parameters for an air classifier using in producing aluminum hydroxide are not fixed values. It depends on specific production requirements, material characteristics, and equipment model, among other factors. Below are some key factors that may influence the optimal operating parameters and general recommendations.

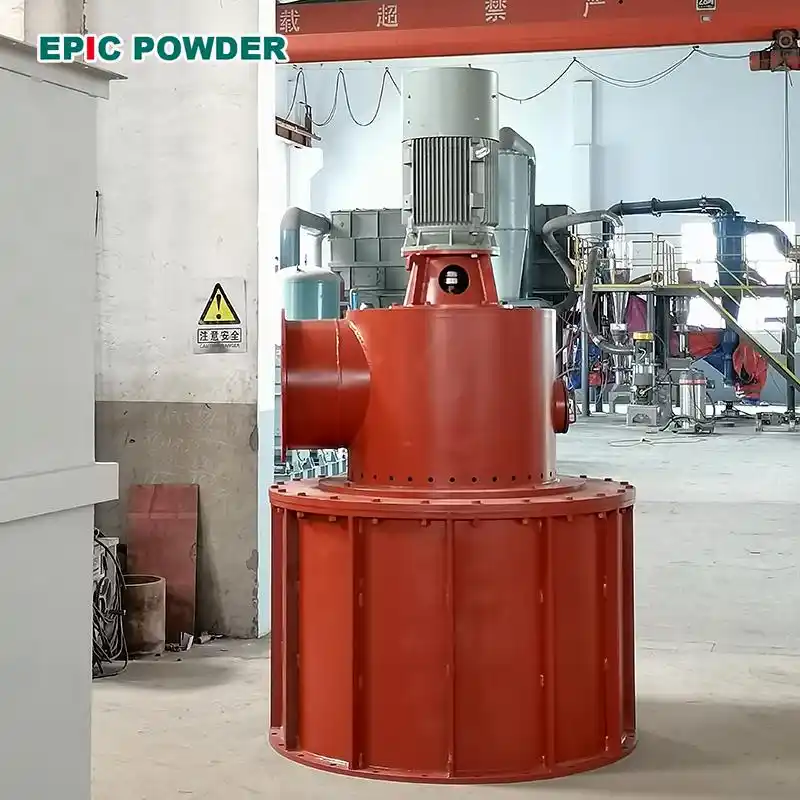

Equipment Model and Specifications

Different models and specifications of aluminum hydroxide classifiers have varying processing capacities, classification fineness, and efficiencies. Therefore, when selecting a classifier, it is essential to choose the appropriate model based on production scale and product quality requirements.

Material Characteristics

The physical properties of aluminum hydroxide (such as particle size distribution, density, and hardness) significantly impact the classification outcome. Based on these material characteristics, operational parameters of the classifier, such as feed rate, classifier wheel speed, and pressure in the classification zone, can be adjusted to achieve optimal results.

General recommendations for optimal operating parameters

• Feed Rate: Should be controlled within the maximum allowable range of the equipment, while avoiding rates that are too high, which could lead to poor classification or equipment overload. The specific rate should be determined based on material characteristics and the equipment model.

• Feed Temperature: Adjust to the suitable range according to material characteristics.

• Classifier Wheel Speed: The speed of the classifier wheel directly affects the classification fineness and efficiency. Generally, higher speeds result in finer particle separation but also increase energy consumption and wear. Thus, adjustment to the optimal level based on actual conditions is necessary.

• Classification Zone Pressure: Stable pressure in the classification zone is crucial for effective separation. Excessively high pressure may cause coarse particle leakage, while excessively low pressure can reduce classification efficiency. Pressure should be adjusted to a suitable range according to material properties and equipment performance.

• Other Parameters: Factors such as feed slurry solid content, temperature, and humidity may also influence classification performance. These parameters should be adjusted and optimized based on the specific situation.

The optimal operating parameters for an aluminum hydroxide classifier need to be determined and adjusted based on the specific circumstances. In practical production, it is recommended to identify the most suitable combination of parameters for the current operating conditions through testing and data analysis. Additionally, regular maintenance and inspection of the classifier to ensure it remains in good working condition are also vital factors for guaranteeing optimal classification performance.

Episches Pulver

Bei Episches Pulver, we understand that every detail in the production process is crucial to the final product. Our team of experts is always ready to support you in determining the optimal operating parameters for your aluminum hydroxide air classifier in your specific application. We are committed to helping you maximize your equipment’s performance and achieve stable, efficient production goals. Please feel free to contact us.