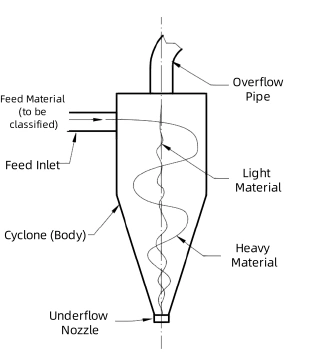

Powder Classification Technology

Powder classification technology is a crucial component in the preparation and processing of powder materials, playing a vital role in their production. In recent years, with the advancement of modern high-tech and new materials industries, the fine powder industry has developed rapidly. The application of ultrafine powders has penetrated various domestic sectors. The demand for […]

Powder Classification Technology Read More »