Silica micro powder is a high-performance inorganic non-metallic material. It’s derived mainly from natural or fused quartz through precise processes like crushing, grinding, magnetic separation, flotation, and acid washing. It has fine particle size, chemical stability, excellent dielectric properties, large surface area, and high thermal conductivity. It plays a critical role in industries such as electronics, chemicals, pharmaceuticals, ceramics, and precision casting. Recently, silica micro powder has become indispensable in advanced fields like aerospace and integrated circuit packaging.

Breaking Stereotypes

Silica micro powder is a common industrial additive, used for thickening, reinforcing, or wear resistance in coatings and fillers.

Produced by grinding and purifying natural or fused quartz, its particle size is minuscule, typically measured in micrometers (μm) or even nanometers (nm).

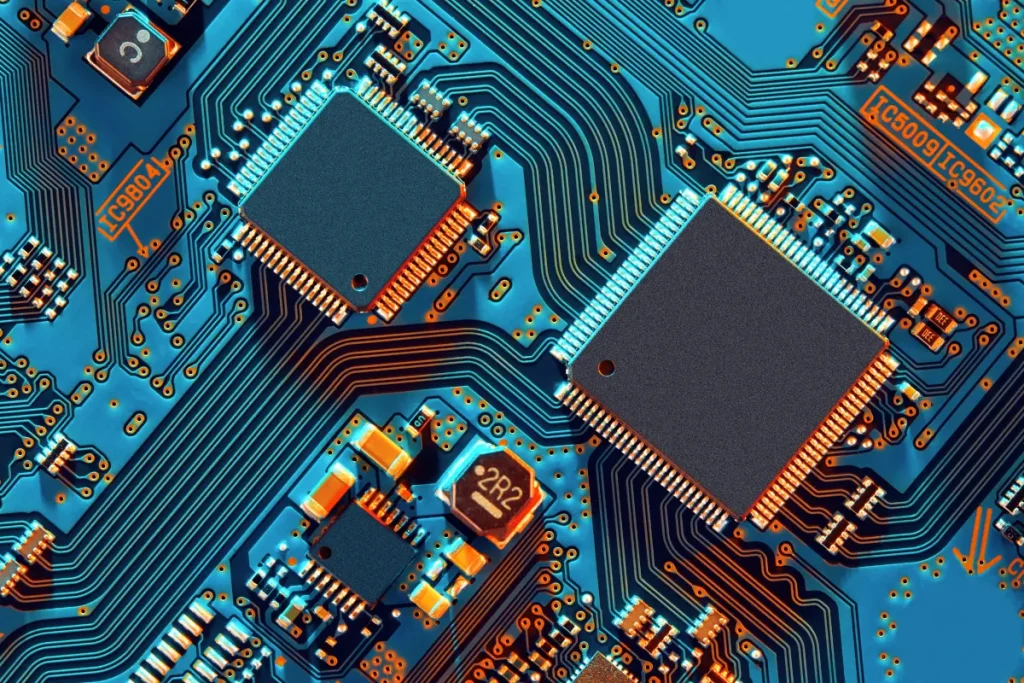

However, it is precisely this material that has undergone a remarkable transformation from a supporting role to a cornerstone within the electronics information industry, particularly in the field of chip packaging. Chip packaging is the critical step that protects the fragile chip core and establishes electrical connections with the external world. The core of the packaging material is a composite known as “Epoxy Molding Compound” (EMC). It constitutes the primary filler material in this composite, accounting for a substantial 80% to 90% of its content. In essence, the black chip casing we see is primarily made of silica micro powder.

Three Core Functions

Cooling Agent: Determining the Chip’s Temperature

With NVIDIA’s GPUs, from H100 to B200, adopting CoWoS packaging technology. It integrates multiple chips densely within a single package—system performance and energy efficiency are significantly enhanced. As GPU power increases, integrating numerous chips onto a silicon interposer creates extremely high cooling demands. If heat cannot be dissipated promptly, it leads to performance degradation (thermal throttling) or even chip failure. Pure epoxy resin has very poor thermal conductivity, similar to a warm blanket. Filling it with high-purity silica micro powder creates efficient pathways for heat conduction, rapidly transferring heat generated by the chip core to the exterior shell for dissipation, ensuring the chip operates efficiently within a safe temperature range.

Stabilizer: Countering Thermal Expansion and Contraction Stress

Chips comprise various materials (silicon, metal, plastic), each with a different Coefficient of Thermal Expansion (CTE). During power cycles and temperature fluctuations, the differential expansion and contraction of these materials generate significant internal stress, capable of breaking the chip’s internal metallic circuits, which are hundreds of times thinner than a human hair. The use of silica micro powder as a filler in EMC offers distinct advantages. Its high purity and low radioactivity effectively reduce the compound’s linear expansion coefficient and shrinkage during curing, while simultaneously enhancing mechanical strength and insulation properties. Incorporating silica micro powder significantly lowers the overall CTE of the EMC, making it more compatible with the silicon die, lead frame, etc. It acts like a “buffer,” effectively absorbing and dispersing stress, thereby ensuring the structural integrity and long-term reliability of the chip under harsh conditions.

Reinforcing Skeleton: Enhancing Packaging’s Mechanical Strength

Unfilled epoxy resin is relatively soft and prone to deformation. It serves as the primary functional filler in EMC, accounting for over 90% of all fillers. Its application significantly enhances the hardness, strength, and modulus of the packaging body, enabling it to withstand external physical shock, vibration, and pressure—like a sturdy suit of “armor” protecting the internal chip.

Not All Silica micro powder is the same

However, not all silica micro powder qualifies as chip lifeblood. Ordinary industrial-grade silica micro powder contains significant metal impurities that can severely impair the chip’s electrical performance. It’s used for chip packaging must meet extremely high standards:

Ultra-High Purity: Metal impurity content must be controlled at ppm (parts per million) or even ppb (parts per billion) levels.

Precise Particle Size Distribution: Spherical silica micro powder with a uniform particle size distribution is required to achieve the highest packing density and optimal flowability.

Perfect Sphericity: Compared to angular powder, spherical silica micro powder exhibits lower stress, better flowability, and higher packing density. It makes it the necessary choice for high-end chip packaging.

ملخص

As chips advance towards 5nm, 3nm, and even smaller nodes, power consumption and heat density increase dramatically, placing near-stringent demands on the thermal management capabilities of packaging materials. Companies like NVIDIA and Intel are already investing in R&D for next-generation chip cooling materials. Concurrently, the rise of advanced packaging technologies like 2.5D/3D packaging and Chiplet requires packaging materials with lower dielectric constants, reduced loss, and higher reliability.

This drives continuous advancement in silica micro powder technology. Higher-purity synthetic spherical silica micro powder, functionalized surface modification techniques, and low-loss fillers tailored for specific frequency bands will become the focal points of R&D for the next generation of “chip lifeblood.” It’s no longer merely a passive filler but a key functional material that actively participates in and determines the performance ceiling of chips.

مسحوق ملحمي

The secret to making those perfect little spheres of silica powder isn’t about grinding them down. It’s about melting them. A special machine called a spheroidization furnace uses a super-hot flame to melt the dusty, jagged particles. When they melt, the natural surface tension pulls each one into a perfect round ball, just like a water droplet.

After the spheres are made, the next most important step is sorting them by size. This is done by an air classifier. Think of it as a super-precise sifter that ensures all the tiny balls are nearly the same size. This is critical because uniformly sized balls pack together tightly. It makes the final chip packaging material better at conducting heat and stronger overall. Epic Powder’s مصنف الهواء does the fine-tuning, making sure the final product is pure enough to make a chip.