When the battery level on your phone is running low, the “battery anxiety” can be overwhelming. As a result, power banks have become a “necessity” during travel or business trips, just like an ID card or wallet. After all, in an unfamiliar environment, a dead phone feels like a digital blackout. Navigation fails, payments are rejected, and you can’t contact anyone. That sense of panic can really throw you off balance. However, recent incidents of power banks catching fire have shaken the industry, sparking widespread discussions about their safety. On June 26, 2025, the Civil Aviation Administration of China issued new regulations banning non-compliant power banks. The Administration required them to be 3C certified before boarding a plane. The issue began on March 20, 2025, when a lithium battery caught fire in the luggage compartment of a flight from Hangzhou to Hong Kong, causing an emergency landing.

1 Why Do Lithium Batteries Catch Fire?

The investigation revealed that the fire was caused by a short circuit in a Romoss 20,000mAh power bank. Then, on May 31 and June 13, two more similar incidents occurred on flights. Safety issues with lithium-ion batteries often manifest as fires or even explosions. The root cause of these problems lies in the thermal runaway inside the battery. Additionally, external factors such as overcharging, fire sources, compression, punctures, and short circuits can also trigger safety issues. Gas release is one of the main signs of lithium-ion battery failure.

When a lithium-ion battery catches fire, it rapidly expels a large amount of white smoke, which is primarily composed of vapor or decomposition products of the battery’s electrolyte. In the early stages of a fire, the difference in smoke color is one of the most noticeable characteristics that distinguish lithium-ion battery fires from common fires. After thermal runaway, the combustible gases released by the battery mix with air to form an explosive mixture. When exposed to the high-temperature particles emitted by the battery, a localized explosion can occur, often accompanied by explosive sounds in the early stages of the fire.

2 Measures to Prevent Lithium Battery Explosions

The safety issues related to lithium-ion batteries are complex and multifaceted. The biggest safety hazard is the random internal short circuit that causes immediate failure, leading to thermal runaway. Therefore, developing and using materials with high thermal stability is the fundamental approach to improving lithium-ion battery safety in the future.

1) Enhancing the Thermal Stability of Battery Materials

Cathode materials: Thermal stability can be improved by optimizing the synthesis conditions, refining synthesis methods, or using doping and surface coating techniques.

Anode materials: The thermal stability of anode materials is influenced by the type of material, the size of the particles, and the stability of the SEI (solid electrolyte interphase) film. The quality of the SEI film directly affects the charging and discharging performance and safety of the battery. Weakly oxidizing the surface of carbon materials or using reduced, doped, or surface-modified carbon materials can improve SEI film quality. Spherical or fibrous carbon materials also help improve SEI quality.

Electrolyte stability: The stability of the electrolyte is related to the type of lithium salt and solvent used. Lithium salts with better thermal stability and solvents with a wider electrochemical window can improve the thermal stability of the battery.

2) Improving Overcharge Protection

To prevent overcharging, specialized charging circuits are typically used to control the battery’s charging and discharging process. Safety valves can be installed on individual batteries to provide additional overcharge protection. A positive temperature coefficient (PTC) resistor can also be used, which increases the internal resistance of the battery as it heats up during overcharging, thus limiting the overcharge current. Specialized separators can also be used. When the temperature of the separator rises too high due to abnormal battery conditions, the pores of the separator shrink and block, preventing the migration of lithium ions and preventing overcharging.

3) Solid-State Batteries

Solid-state batteries use solid electrolytes to replace the flammable liquid electrolytes found in traditional liquid batteries. This fundamentally eliminates the safety risks associated with electrolyte leakage and combustion, raising the thermal runaway temperature from 120°C to above 200°C. Solid-state batteries are also less likely to short-circuit, catch fire, or explode when subjected to external forces such as punctures. Even if the battery is pierced with a nail, cut, or bent, it can still remain stable.

3 The performance of lithium batteries

Now, let’s introduce the analysis methods of lithium battery charging and discharging curves, including charging efficiency, discharge characteristics, capacity evaluation, internal resistance evaluation, and cycle life evaluation. By interpreting the charging and discharging curves, we can gain an in-depth understanding of the battery’s performance and characteristics, providing important guidance for battery selection, usage, and optimization.

The performance of lithium batteries is crucial for the operation of various electronic devices and power tools. Charging and discharging curves are one of the key methods for evaluating lithium battery performance, as they can visually reflect the voltage and current changes during the charging and discharging process. By analyzing these curves, we can obtain information on key parameters such as battery capacity, internal resistance, and efficiency, which in turn provides guidance for optimizing battery design and improving performance.

4 Analysis of Lithium Battery Charging Curve

The charging and discharging curve of a lithium battery represents the relationship between the battery’s voltage and discharge capacity, as well as the state of charge (SOC) curve. During the charging process, the voltage gradually increases while the current decreases. The slope of the charging curve reflects the charging speed; the steeper the slope, the faster the charging speed. Meanwhile, the plateau region of the charging curve indicates that the battery is fully charged. The voltage tends to stabilize.

Charging efficiency is an important indicator for evaluating battery charging performance. A higher charging efficiency means the battery can more effectively convert the input electrical energy into stored chemical energy. By comparing the actual charging capacity from the charging curve with the theoretical charging capacity, we can assess the charging efficiency. Additionally, energy loss during the charging process can be observed to identify methods for improving charging efficiency.

The charging termination voltage refers to the voltage value when the battery is fully charged. Properly setting the charging termination voltage helps avoid overcharging and prolong the battery’s lifespan. By analyzing the charging curve, an appropriate charging termination voltage can be determined to ensure the battery charges within a safe range.

5 Analysis of Lithium Battery Discharge Curve

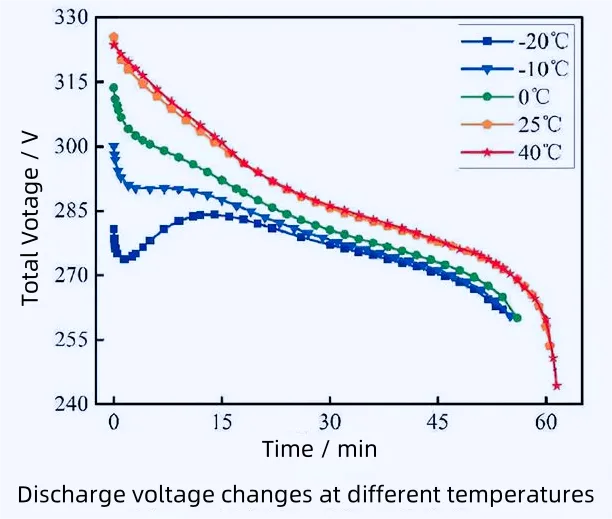

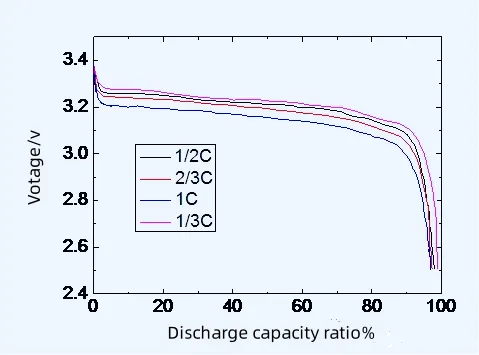

During discharge, the voltage gradually decreases, and the current also decreases accordingly. The shape and slope of the discharge curve can provide important information about the battery’s performance. A flatter discharge curve usually indicates that the battery has good discharge stability and can provide stable energy output. Additionally, by observing the plateau region of the discharge curve, we can understand the voltage variation of the battery at different discharge depths and evaluate the battery’s discharge capability.

The area under the discharge curve is proportional to the discharge time. By calculating the area beneath the curve, we can evaluate the battery’s discharge capacity. The discharge capacity directly impacts the battery’s usage time and endurance.

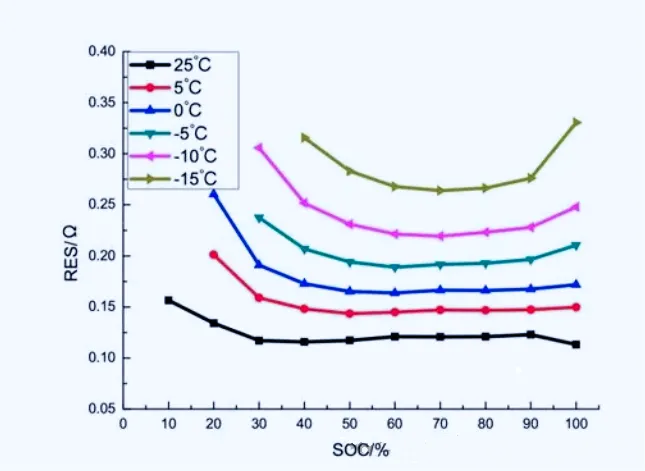

6 Internal Resistance Impact

Internal resistance is the resistance within the battery, which affects the discharge characteristics. Higher internal resistance leads to a quicker voltage drop and reduced discharge power. By analyzing the discharge curve, we can estimate the battery’s internal resistance and assess its impact on battery performance.

7 Capacity Evaluation

The capacity of a lithium battery refers to the amount of charge it can store. It’s typically measured in milliamp-hours (mAh) or amp-hours (Ah). By integrating the charging and discharging curves, we can calculate the battery’s actual capacity. Additionally, multiple charge and discharge cycle tests can be performed to observe the capacity decay and evaluate the battery’s cycle life.

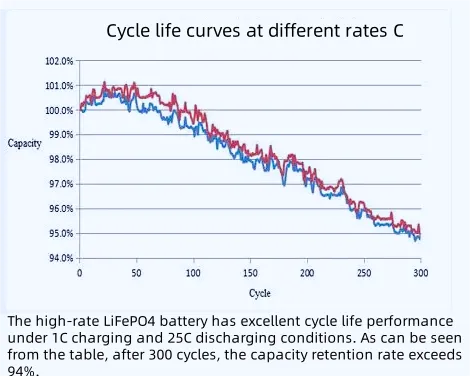

8 Cycle Life Evaluation

Cycle life refers to the ability of a battery to maintain certain performance levels after multiple charge and discharge cycles. By observing the changes in the charge and discharge curves over several cycles, we can assess the battery’s cycle life. If the shape and characteristics of the curve remain relatively stable after multiple cycles, it indicates that the battery has good cycle life. Additionally, capacity decay during the cycle process can be analyzed to predict the battery’s overall lifespan.

Conclusion

The charging and discharging curve of a lithium battery represents the relationship between the battery’s voltage and discharge capacity, as well as the remaining capacity (SOC) curve. It is an important method for better analyzing and evaluating battery performance. By analyzing charging efficiency, discharge characteristics, capacity, internal resistance, and cycle life, a comprehensive understanding of the battery’s performance can be achieved. This analytical approach is crucial for battery design optimization, quality control, and application selection. In practical applications, combining various testing methods and data analysis techniques allows for a more accurate evaluation of lithium battery performance, ensuring the reliable operation of various electronic devices and power tools.

At Epic Powder Machinery, we specialize in high-quality jet mills and powder processing solutions, providing cutting-edge technology to optimize powder performance and enhance efficiency across various industries. Get in touch with us today to explore how our equipment can elevate your production process.