In recent years, Chinese manufacturers have made steady progress in developing high-performance metal powders, gradually reducing reliance on imported materials. While significant breakthroughs have been achieved in some areas, certain specialized powders still require further technological advancement. This article examines eight types of high-end metal powders where domestic production continues to face challenges, highlighting both current capabilities and remaining gaps.

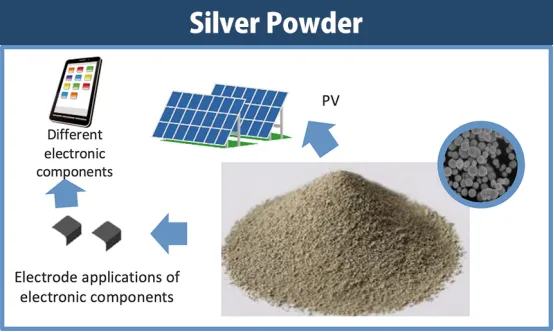

1 High-End Silver Powder for Photovoltaics

Photovoltaic silver paste is a core material for solar cell electrodes, composed of silver powder, resin binder, solvent, additives, and glass powder. China’s high-end silver powder was long dependent on imports due to shortcomings in batch stability, particle size control, and dispersion performance. As a result, the market was dominated by Japan’s Dowa Holdings and the U.S.-based AMES, posing a supply chain risk.

2 Nanoscale Nickel Powder for MLCCs

The raw materials for multilayer ceramic capacitors (MLCCs) include ceramic and metal powders. However, China still relies on imports for high-end MLCC core materials. For instance, nanoscale nickel powder for MLCCs is primarily monopolized by Japanese manufacturers.

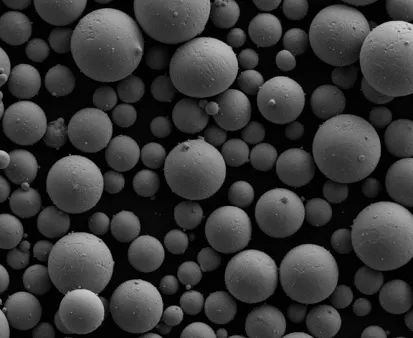

3 Spherical Titanium Alloy Powder for 3D Printing

Canada’s AP&C holds a monopoly on plasma atomization technology, supplying over 50% of the global powder bed 3D printing market with high-end spherical titanium alloy powder. Most of China’s demand for such powders is met through imports.

4 High-End Superalloy Powder

Powder superalloys, made from metal powders and processed via thermal methods, offer high tensile strength and fatigue resistance. After three generations of development, they are widely used in critical components like turbine disks for advanced military and civil aircraft engines. However, China still heavily relies on imported superalloy powders.

5 Lightweight, High-Strength Aluminum Alloy Powder

With growing demand for weight reduction in defense equipment, additive manufacturing of aluminum alloy parts has become increasingly urgent. Currently, common powders like AlSi10Mg have tensile strengths below 400 MPa, insufficient for aerospace applications. High-strength aluminum alloy powders remain import-dependent.

6 Ultra-Pure Nanoscale Copper Powder

Nanoscale copper powder (1–100 nm) exhibits unique properties like the small-size effect, surface effect, quantum tunneling effect, and excellent conductivity. It is widely used in catalysts, conductive adhesives, lubricant additives, and toughening materials. However, producing high-purity, narrowly distributed, and highly dispersible nanocopper powder remains technically challenging. China still lags behind Western nations in copper processing, relying heavily on imports for high-end products.

7 High-End Cobalt Powder

With the rapid growth of new energy vehicles (NEVs), 5G communications, and aerospace industries, demand for cobalt powder continues to rise. In NEVs, cobalt powder is a key material for lithium-ion battery cathodes. Yet, uneven resource distribution (60% from the Democratic Republic of Congo), volatile supply chains, and technological monopolies by U.S., European, and Japanese firms (e.g., Haynes International, Showa Denko) have hindered China’s industry development.

8 High-Quality High-Speed Steel Powder

Powder metallurgy high-speed steel (PM-HSS) is produced by compacting and sintering metal powders, followed by thermal processing. Challenges like coarse particles, powder boundary defects, ceramic inclusions, and narrow sintering windows limit performance. Despite increasing demand, China still imports most high-quality PM-HSS.

Epic Powder

As domestic production of these metal powders continues to improve, advanced manufacturing equipment will play an increasingly important role. At Epic Powder Machinery, we focus on developing reliable and efficient powder production systems to support the growing needs of manufacturers. Our equipment is designed to help producers achieve better quality control and higher productivity in metal powder manufacturing.

For more information about our powder processing solutions, please contact our technical team. We’re committed to supporting the development of China’s advanced materials industry through practical, high-performance equipment.